- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

IBM35

DAWSON

This machine is equipped with a highly efficient three-station system that includes injection molding for preform production, blowing for shaping the bottle, and product release for seamless unloading. The process starts with raw materials being fed from the hopper into the injection screw, which then injects the material to form the preform. The preforms are then automatically rotated by the plate to the blowing station, where they are heated by their own heat, eliminating the need for any additional reheating during the blowing process. This not only reduces energy consumption but also improves production efficiency.

Once the preforms are blown into their final bottle shape, they rotate to the release station, where they are automatically ejected from the machine and fall into a collection area, ready for packaging or further processing. The entire process follows a fully automated, cyclic rotation mode, ensuring smooth, continuous production without any manual intervention. The absence of a need for separate bottle preforms further reduces waste and enhances overall production efficiency. Additionally, the machine is designed to work with high precision, producing bottles with a smooth and attractive finish, free from defects.

This fully automated system offers significant advantages, such as increased productivity, minimal human error, and consistent high-quality output. It is particularly well-suited for producing various types of plastic bottles, including those used in the cosmetic industry (10-1000 ml plastic cosmetic bottles), milk bottles, pharmaceutical packaging, PC bottles, red wine cups, LED lampshades, and many other products requiring precision and quality. The machine's ability to work without the need for bottle preforms results in reduced material waste and lower production costs, making it an ideal choice for businesses looking to optimize their blow molding processes while maintaining high standards of quality and sustainability.

Moreover, the machine is designed with flexibility in mind, capable of handling a wide range of applications in industries like cosmetics, pharmaceuticals, food and beverage, and electronics. Its automated features also reduce labor costs and ensure a smoother workflow, increasing the overall efficiency of the production line. With high precision and an advanced automated cycle, the machine ensures that finished products meet the highest quality standards, with consistently smooth surfaces and flawless finishes.

|  |

Technical Parameters

| IBM35D | |||

| Item | Unit | Date | |

| Injection system | Screw Diameter | mm | 40 |

| Max. Theoretical injection capacity | G | 176 | |

| Heating capacity | KW | 7.2 | |

| No. of heating area | Qty | 3 | |

| Clamping & blowing system | Clamping force of injection | kn | 350 |

| Clamping force of blowing | kn | 40 | |

| Opening stroke of mold platen | mm | 120 | |

| Max. Platen size (L×W) | mm | 420×340 | |

| Min. Mold thickness (H) | mm | 180 | |

| Heating capacity of mould | KW | 2.8 | |

| Product dimension range | Suitable bottle range | ml | 3-800 |

| Max. bottle height | mm | ≤180 | |

| Max. Dia. of bottle | mm | ≤80 | |

| Dry cycle | s | 4 | |

| Hydraulic driving system | Motor power | KW | 11/15 |

| hydraulic pressure | Mpa | 14 | |

| Pneumatic system | Min. Air pressure | Mpa | ≥0.8 |

| Discharge rate of compressed air | M3/mm | ≥0.7 | |

| Cooling system | Water flowage | M3/h | 3 |

| Total rated power with mold heating | KW | 21/25 | |

| Machine information | Dimension | M | 3.1×1.2×2.2 |

| machine weight | Ton | 4.0 | |

Machine Advantages

Bottle is a container that can hold liquid or solid, which can be seen everywhere in our life, including medicine bottle, cosmetics bottle and beverage bottle. Due to the rapid development of the petroleum industry, human beings invented high molecular polymer, which is commonly known as plastics. Since then, our bottle materials have changed from single glass or ceramics to various kinds of plastics. Drawing lessons from the long history of glass container blowing process, the extrusion or injection molding plastic mold in relativistic state is placed in the blowing mold, and the mold is inflated by a certain pressure of compressed air to make it close to the cavity wall. After cooling and setting, the mold is demolished to obtain the plastic hollow products with the same shape as the cavity. This is the hollow blow molding process we are familiar with.

| our own engineers team, we have more then 18 years experience in this field. 1. The servo motor of our machine uses PHASE from Italy, it is the best supplier of servo motors. 2. The cylinder drive has been upgraded to a single cylinder, which is more stable and stronger. Life is also longer than the others. |

| Our pneumatic valve uses FESTO Germany, which is the first quality in the world. Its purchase cost itself is very high, but the quality is very stable and the service life is very long. |  |

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

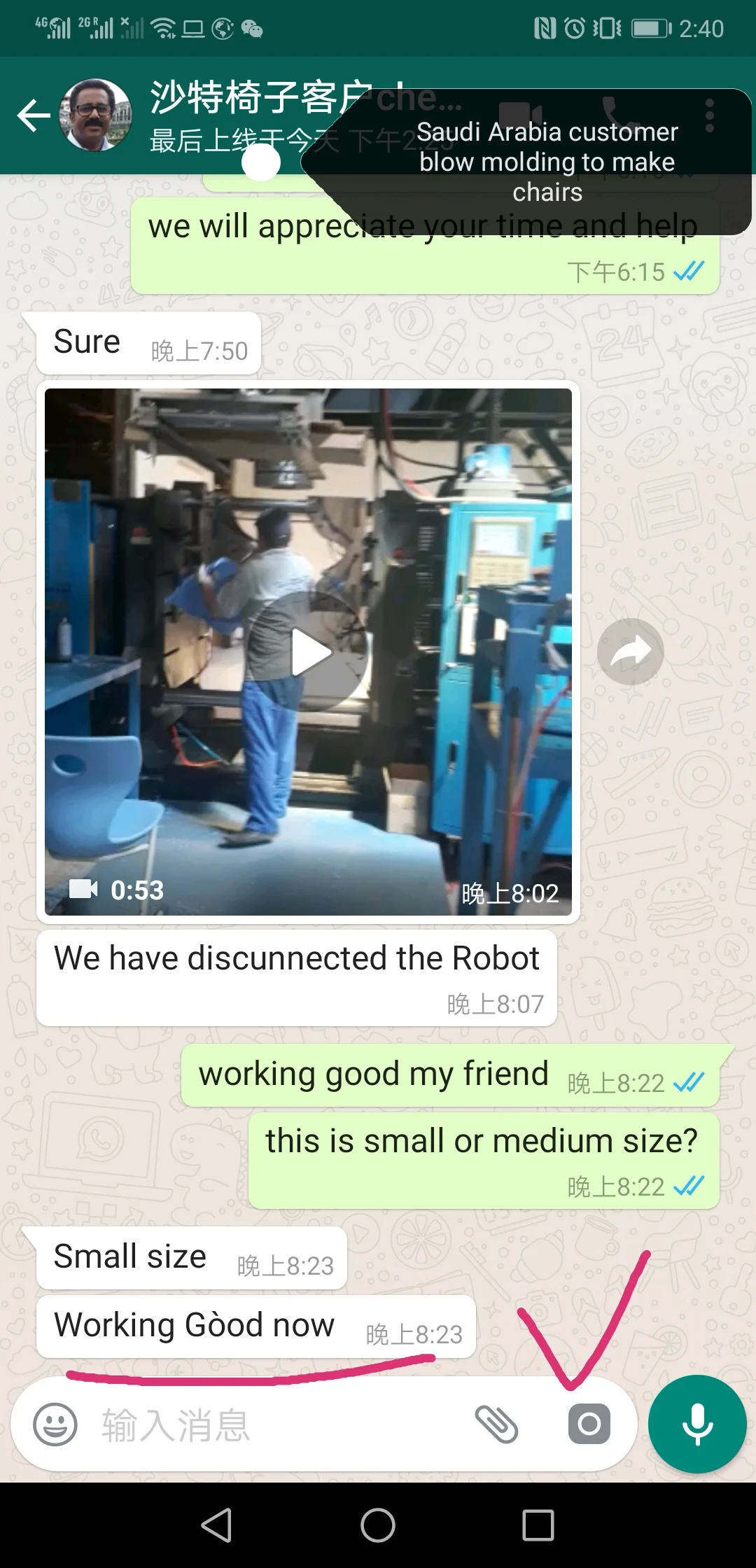

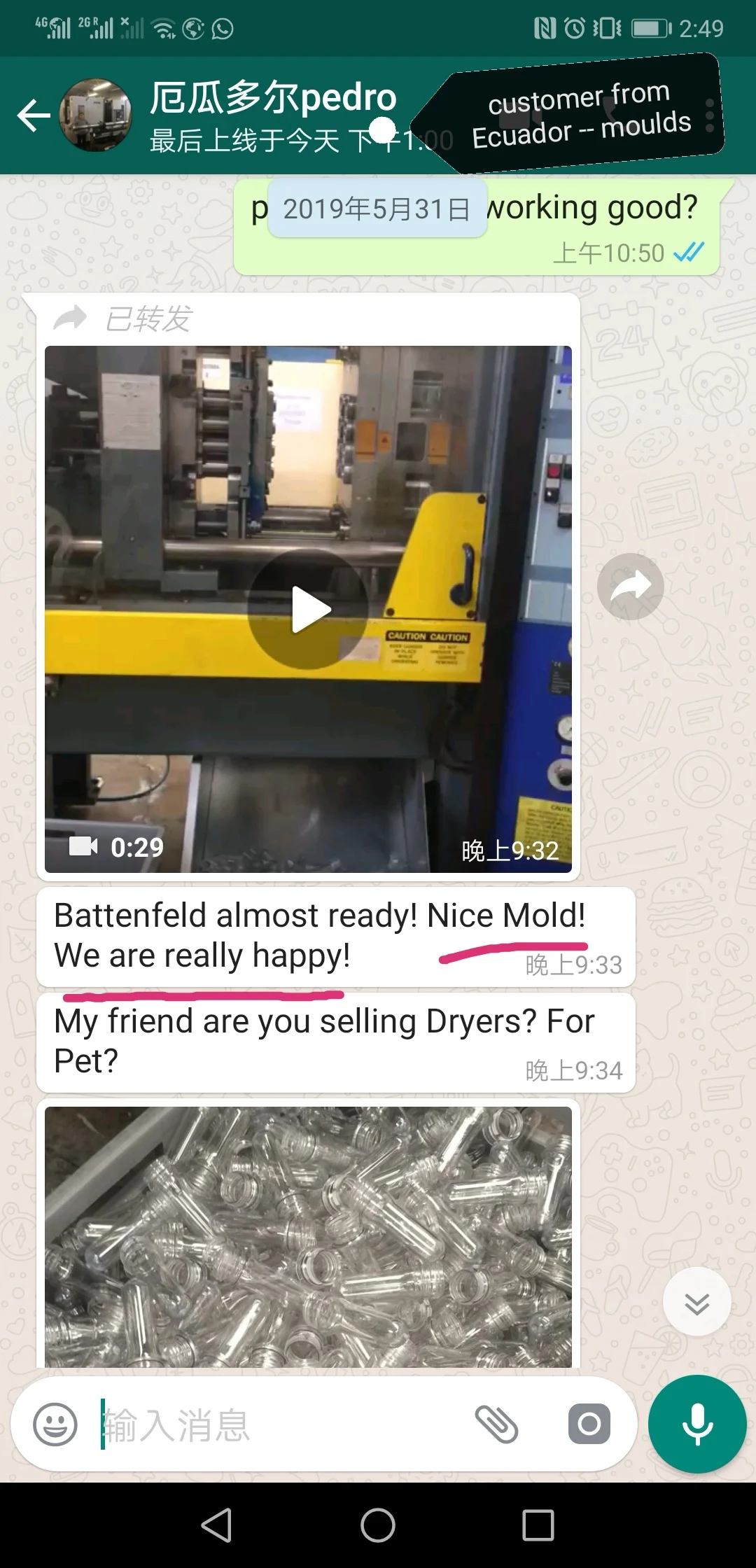

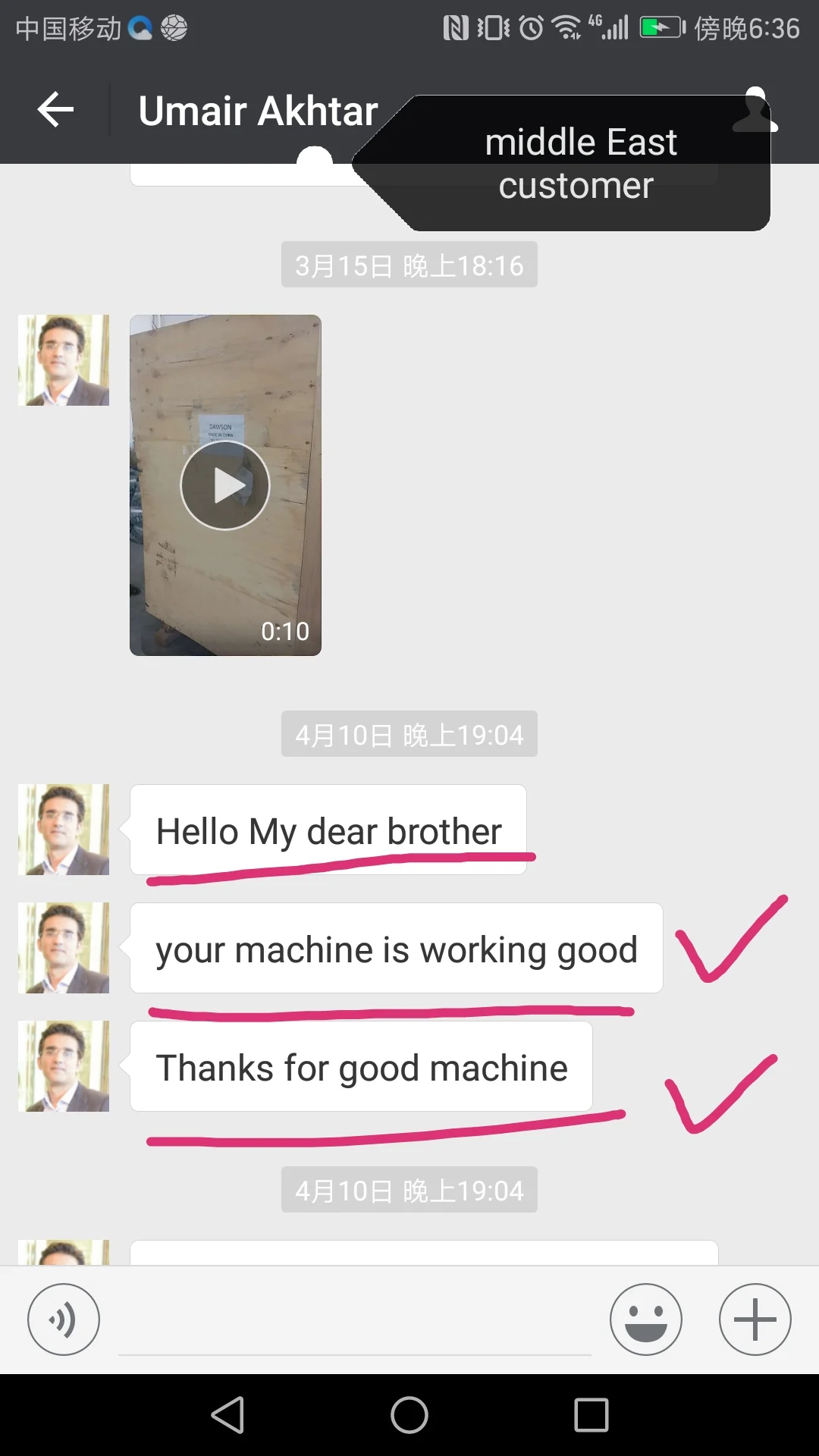

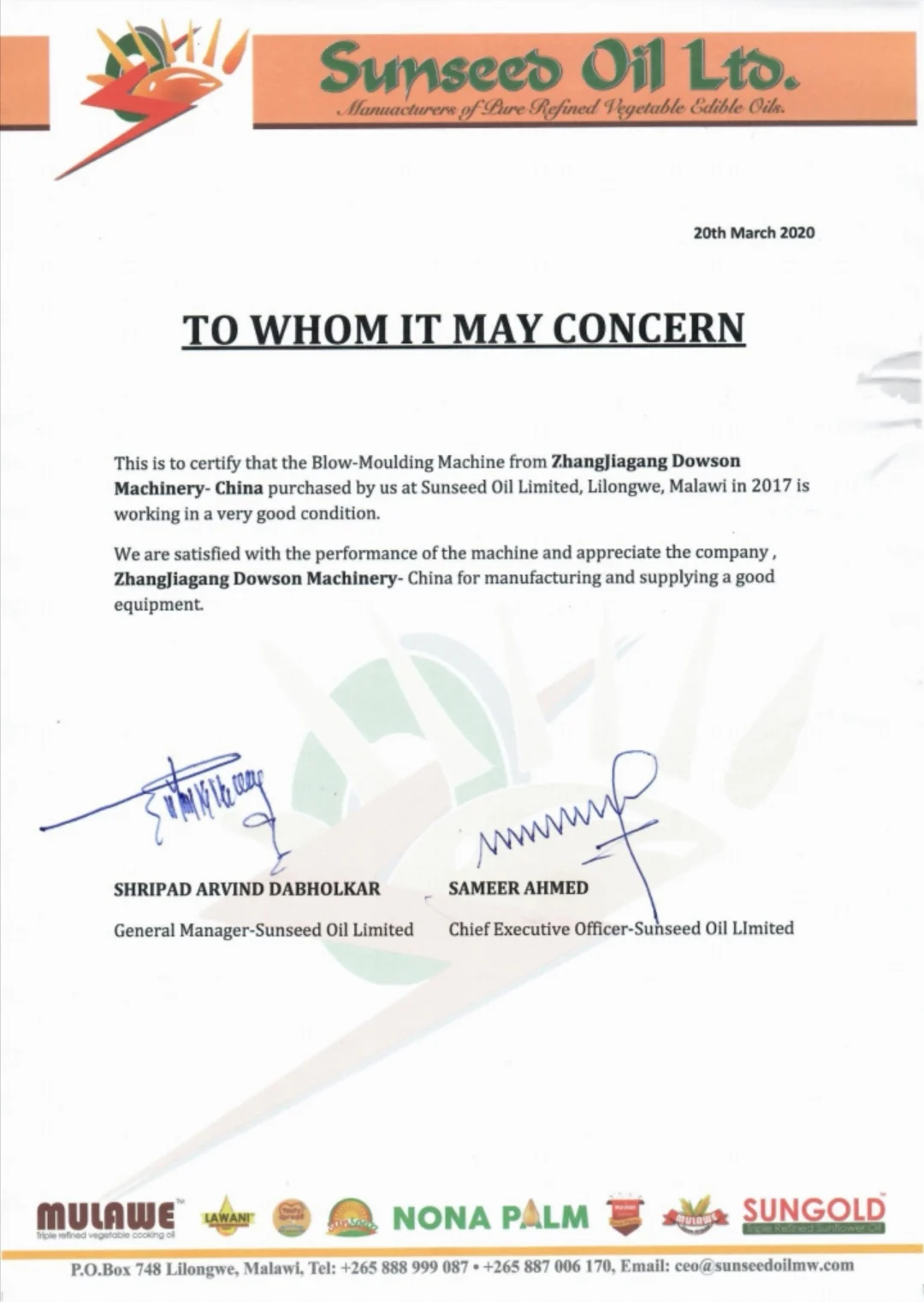

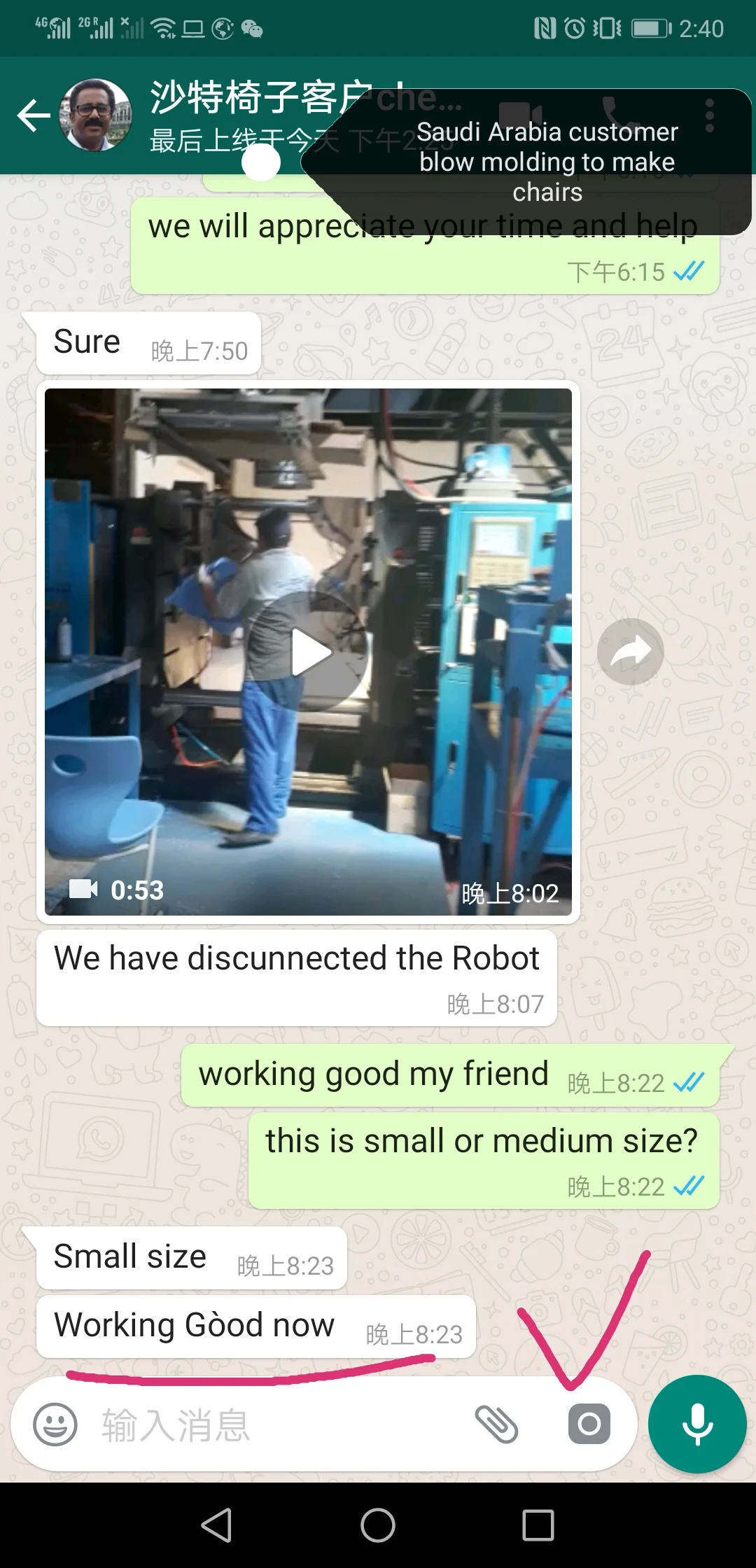

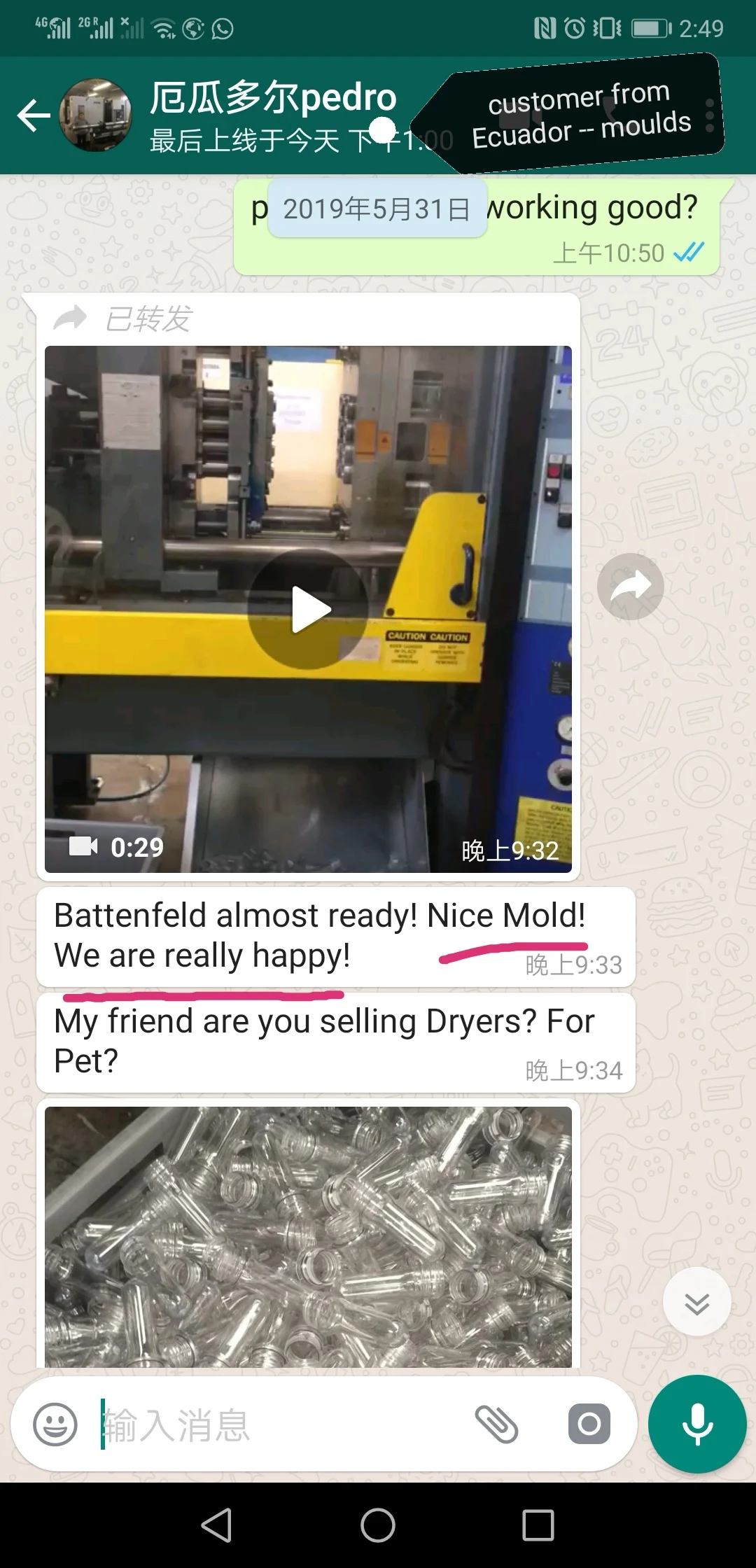

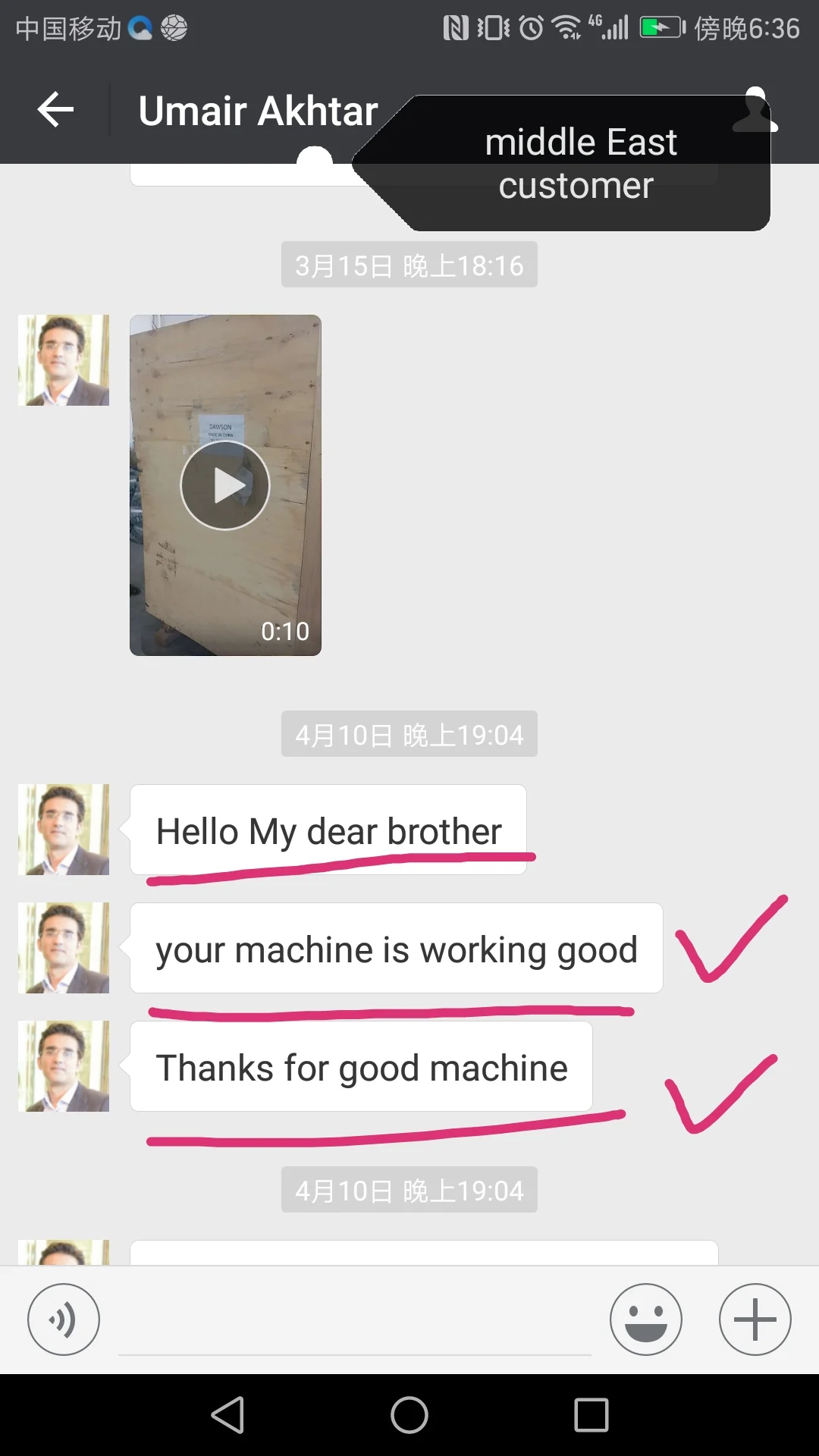

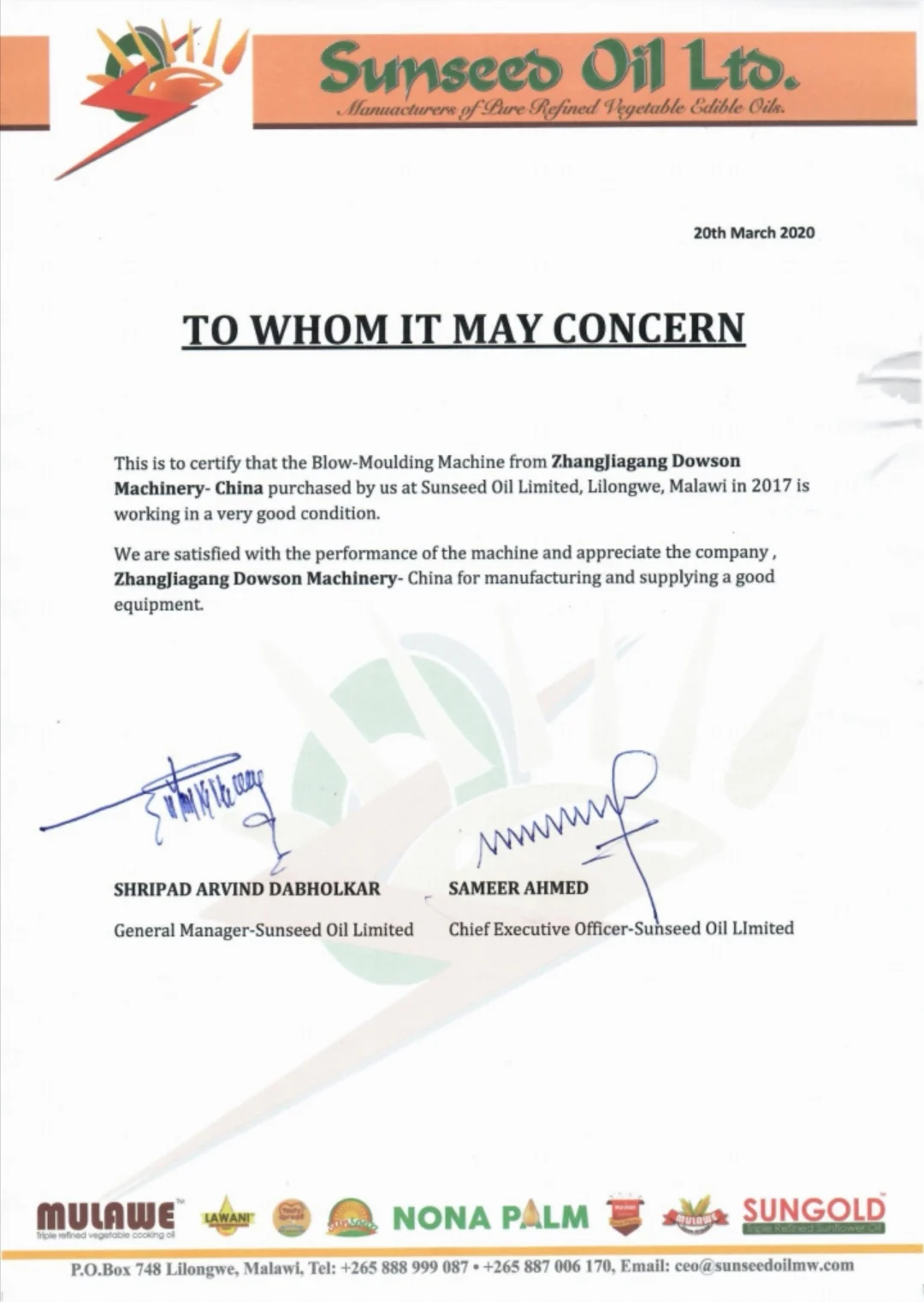

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |

This machine is equipped with a highly efficient three-station system that includes injection molding for preform production, blowing for shaping the bottle, and product release for seamless unloading. The process starts with raw materials being fed from the hopper into the injection screw, which then injects the material to form the preform. The preforms are then automatically rotated by the plate to the blowing station, where they are heated by their own heat, eliminating the need for any additional reheating during the blowing process. This not only reduces energy consumption but also improves production efficiency.

Once the preforms are blown into their final bottle shape, they rotate to the release station, where they are automatically ejected from the machine and fall into a collection area, ready for packaging or further processing. The entire process follows a fully automated, cyclic rotation mode, ensuring smooth, continuous production without any manual intervention. The absence of a need for separate bottle preforms further reduces waste and enhances overall production efficiency. Additionally, the machine is designed to work with high precision, producing bottles with a smooth and attractive finish, free from defects.

This fully automated system offers significant advantages, such as increased productivity, minimal human error, and consistent high-quality output. It is particularly well-suited for producing various types of plastic bottles, including those used in the cosmetic industry (10-1000 ml plastic cosmetic bottles), milk bottles, pharmaceutical packaging, PC bottles, red wine cups, LED lampshades, and many other products requiring precision and quality. The machine's ability to work without the need for bottle preforms results in reduced material waste and lower production costs, making it an ideal choice for businesses looking to optimize their blow molding processes while maintaining high standards of quality and sustainability.

Moreover, the machine is designed with flexibility in mind, capable of handling a wide range of applications in industries like cosmetics, pharmaceuticals, food and beverage, and electronics. Its automated features also reduce labor costs and ensure a smoother workflow, increasing the overall efficiency of the production line. With high precision and an advanced automated cycle, the machine ensures that finished products meet the highest quality standards, with consistently smooth surfaces and flawless finishes.

|  |

Technical Parameters

| IBM35D | |||

| Item | Unit | Date | |

| Injection system | Screw Diameter | mm | 40 |

| Max. Theoretical injection capacity | G | 176 | |

| Heating capacity | KW | 7.2 | |

| No. of heating area | Qty | 3 | |

| Clamping & blowing system | Clamping force of injection | kn | 350 |

| Clamping force of blowing | kn | 40 | |

| Opening stroke of mold platen | mm | 120 | |

| Max. Platen size (L×W) | mm | 420×340 | |

| Min. Mold thickness (H) | mm | 180 | |

| Heating capacity of mould | KW | 2.8 | |

| Product dimension range | Suitable bottle range | ml | 3-800 |

| Max. bottle height | mm | ≤180 | |

| Max. Dia. of bottle | mm | ≤80 | |

| Dry cycle | s | 4 | |

| Hydraulic driving system | Motor power | KW | 11/15 |

| hydraulic pressure | Mpa | 14 | |

| Pneumatic system | Min. Air pressure | Mpa | ≥0.8 |

| Discharge rate of compressed air | M3/mm | ≥0.7 | |

| Cooling system | Water flowage | M3/h | 3 |

| Total rated power with mold heating | KW | 21/25 | |

| Machine information | Dimension | M | 3.1×1.2×2.2 |

| machine weight | Ton | 4.0 | |

Machine Advantages

Bottle is a container that can hold liquid or solid, which can be seen everywhere in our life, including medicine bottle, cosmetics bottle and beverage bottle. Due to the rapid development of the petroleum industry, human beings invented high molecular polymer, which is commonly known as plastics. Since then, our bottle materials have changed from single glass or ceramics to various kinds of plastics. Drawing lessons from the long history of glass container blowing process, the extrusion or injection molding plastic mold in relativistic state is placed in the blowing mold, and the mold is inflated by a certain pressure of compressed air to make it close to the cavity wall. After cooling and setting, the mold is demolished to obtain the plastic hollow products with the same shape as the cavity. This is the hollow blow molding process we are familiar with.

| our own engineers team, we have more then 18 years experience in this field. 1. The servo motor of our machine uses PHASE from Italy, it is the best supplier of servo motors. 2. The cylinder drive has been upgraded to a single cylinder, which is more stable and stronger. Life is also longer than the others. |

| Our pneumatic valve uses FESTO Germany, which is the first quality in the world. Its purchase cost itself is very high, but the quality is very stable and the service life is very long. |  |

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |