Unleash Your Manufacturing Potential: Unlock Our Injection Molding Machines

Discover Our Selection of Injection Molding Machines

Product series of PET preform injection molding machine

Economic Series

Efficient Series

Empowering Possibilities: Discover Injection Molding Machine Applications

Unlock the full potential of your production capabilities with our versatile injection molding machines. Designed to handle a wide range of materials and complex shapes, our machines are perfect for producing high-quality products across various industries. Explore the diverse applications and see how our technology can be tailored to meet your specific needs.

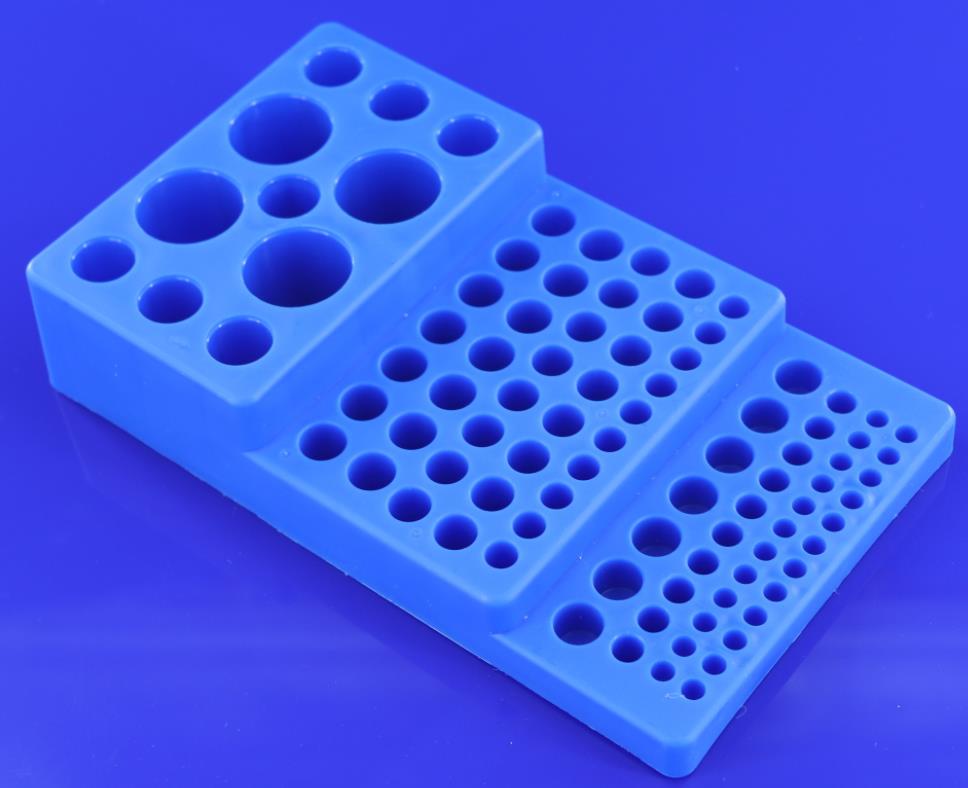

Injection Molding Machine Advantages for Plastic Bottle Caps Production

Elevate your production of plastic bottle caps with our state-of-the-art injection molding machines. Designed to handle a variety of plastic materials, our machines offer flexibility, efficiency, and high-quality output that can transform your cap manufacturing process.

Streamlined Production Process

The injection molding process for plastic caps involves melting the plastic material and injecting it into a pre-designed mold under high pressure. This ensures precise replication of details and uniformity in cap size and thickness. Our machines optimize this process through advanced temperature control systems that maintain consistent melt conditions, thereby reducing defects like warping or shrinkage.

High-Speed Capabilities

Speed is crucial in high-volume production environments. Our injection molding machines are designed for rapid cycle times without compromising the quality of the end product. This means you can achieve higher throughput rates and meet market demands more effectively.

Energy Efficiency

Reducing operational costs while maintaining high output is vital. Our machines are engineered to be energy-efficient, using less power per cycle while maintaining peak performance levels. This not only lowers your utility costs but also supports your sustainability goals by reducing environmental impact.

Quality Assurance

Every machine comes equipped with precision quality control features that ensure each cap meets stringent industry standards before it leaves the production line. Automated inspection systems check for consistency in dimensions and structural integrity, guaranteeing that only the best products reach your customers.

Injection Molding Machine: Your Questions, Our Answers

What is an Injection Molding Machine?

An Injection Molding Machine, also known as an injection molding equipment or an extrusion press, is a device that manufactures plastic parts by injecting molten plastic resin into a mold cavity under high pressure. The process solidifies the material into the desired shape.

How does it work?

What types of materials can be processed with an IMM?

What's the importance of precision in an Injection Molding Machine?

How do I choose the right size or capacity for my business needs?