- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Suitable Material: | |

|---|---|

| Die Head: | |

| Color: | |

| Warranty: | |

| Showroom location: | |

| Automation: | |

| Availability: | |

| Quantity: | |

DSB75

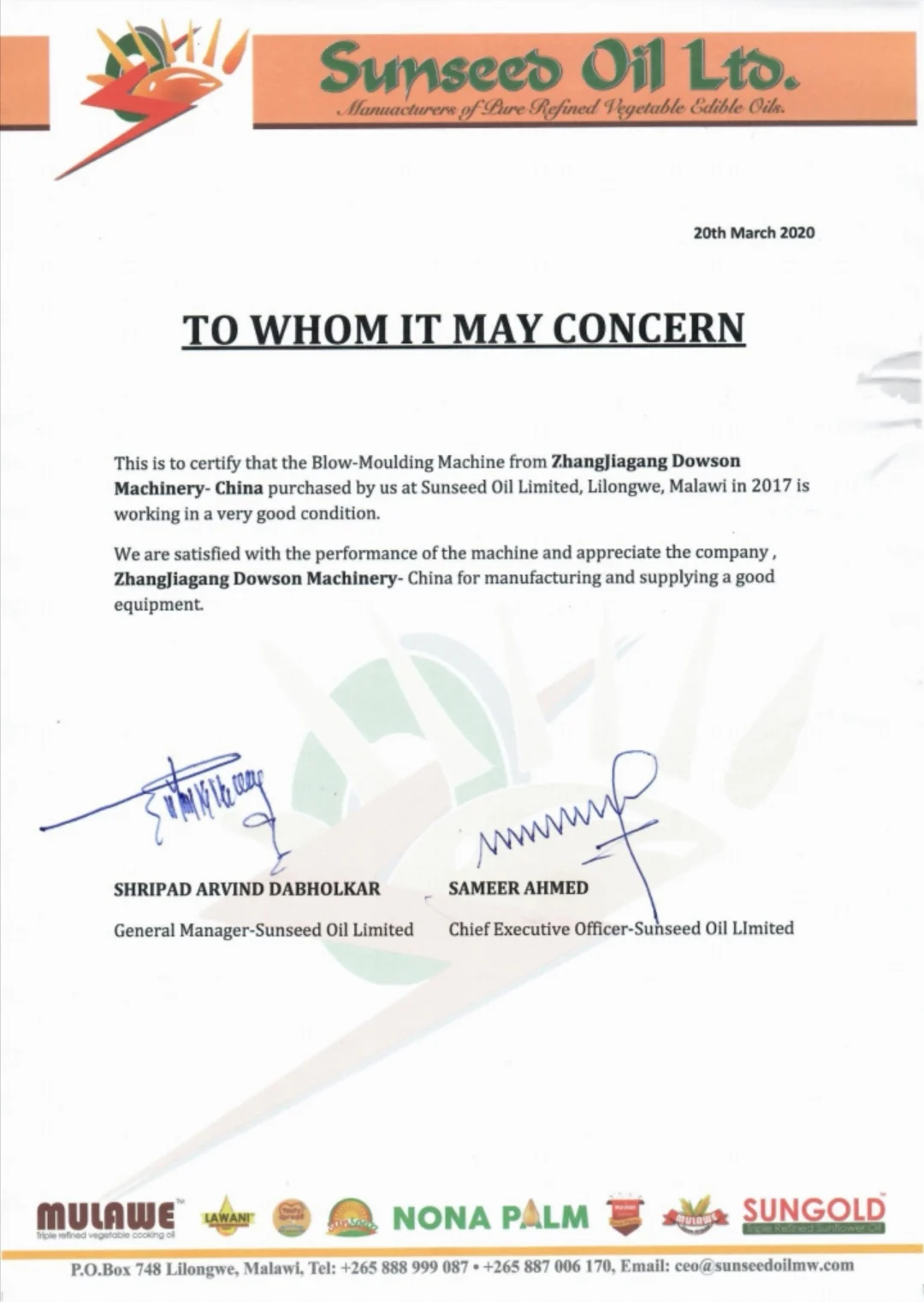

DAWSON

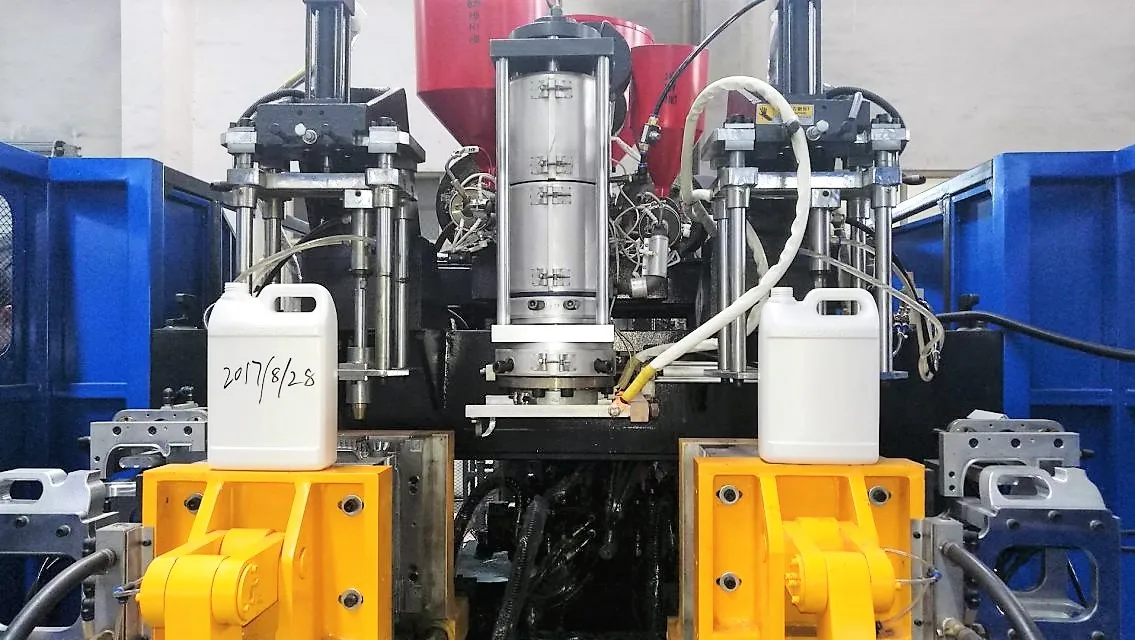

The Extrusion Blow Molding Machine DSB65/75 represents a pinnacle of advanced manufacturing technology in the field of plastic processing. This state - of - the - art machine is designed with precision and versatility in mind, making it an ideal choice for a wide range of plastic product manufacturing needs.

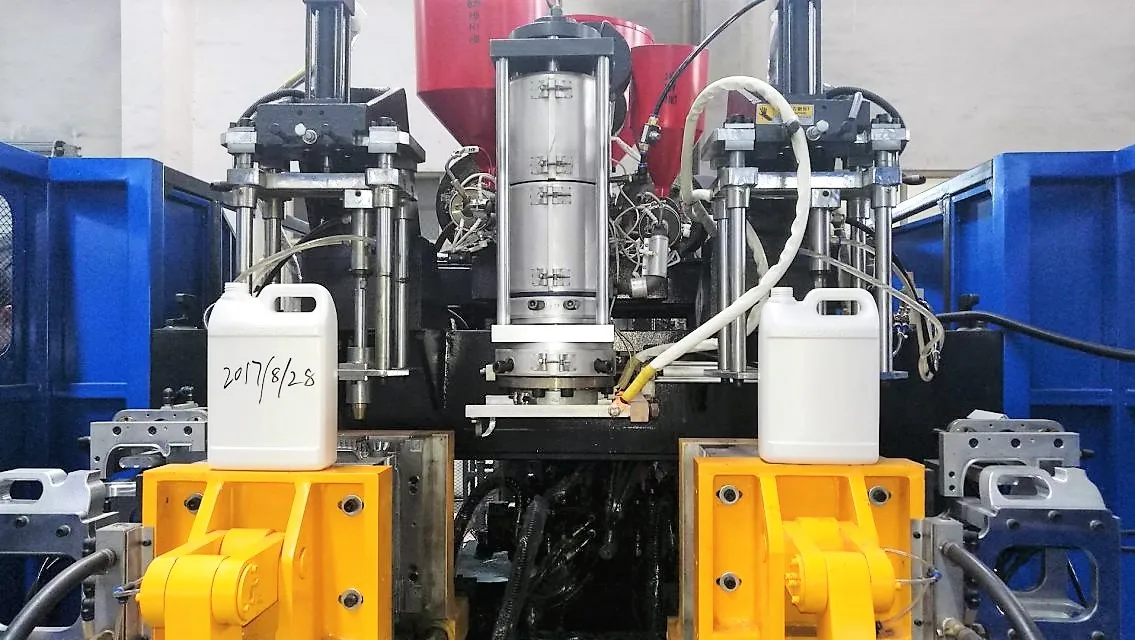

It is highly suitable for the production of an extensive array of plastic items. When it comes to plastic bottles, it can craft everything from small - sized, 50ml bottles that are commonly used for storing essential oils, sample - sized cosmetics, or single - use medications, to larger 5L bottles which find applications in the beverage industry for packaging juices, water, or even in the industrial sector for storing chemicals and cleaning agents.

For jars, the DSB65/75 can create various styles, whether it's the small, delicate jars for facial creams and ointments or the more robust ones for storing food products like jams, honey, and pickles. These jars are produced with high - quality finishes, ensuring both aesthetic appeal and excellent functionality.

In the realm of small containers, this machine proves its mettle. It can manufacture containers for storing office supplies such as glue, correction fluid, and small stationery items, as well as containers for household use, like those for storing spices, small hardware, or craft materials.

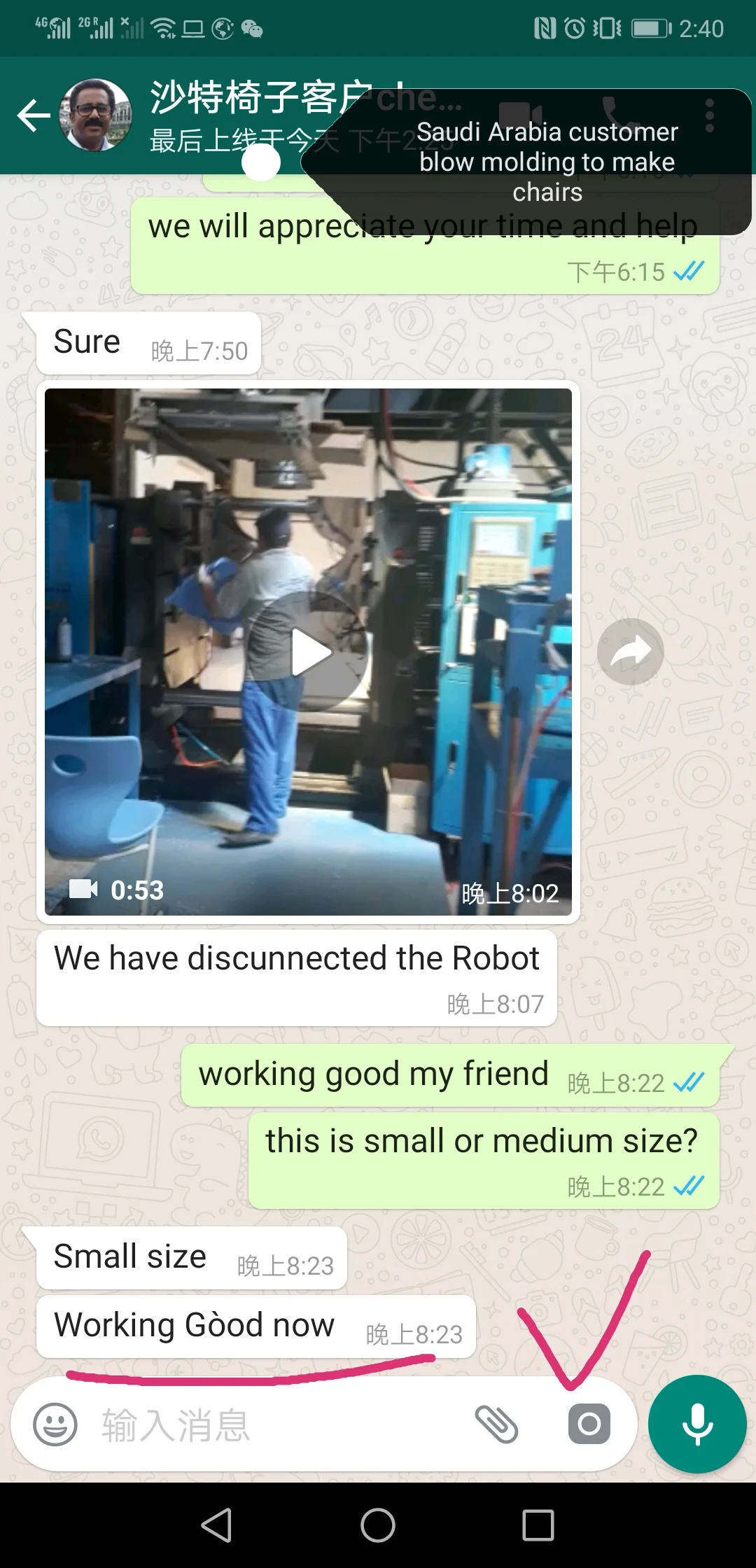

Moreover, when it comes to jerrycans, the DSB65/75 is capable of producing them in the 50ml - 5L range. These jerrycans are perfect for storing and transporting fuels for small - scale machinery, water for outdoor activities, or other liquids in agricultural and DIY settings.

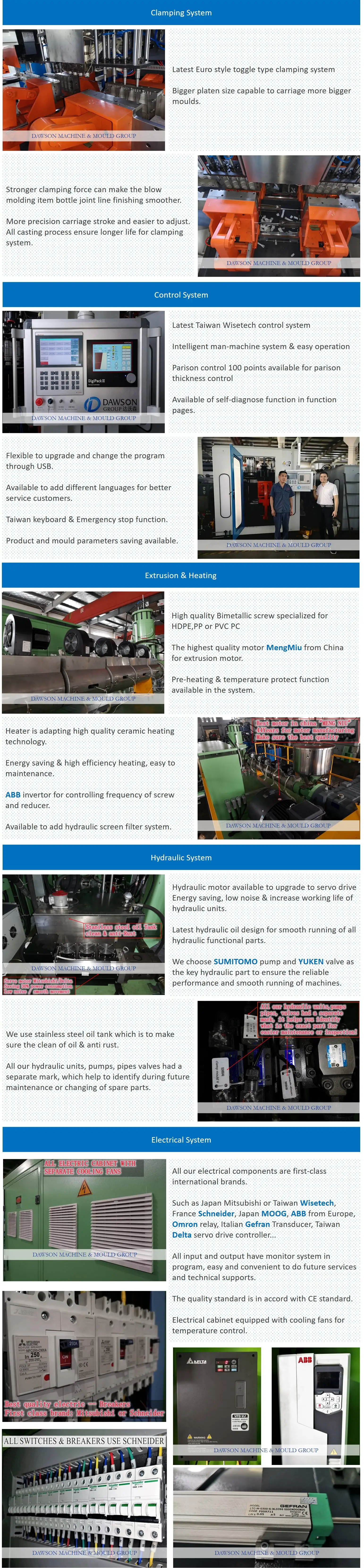

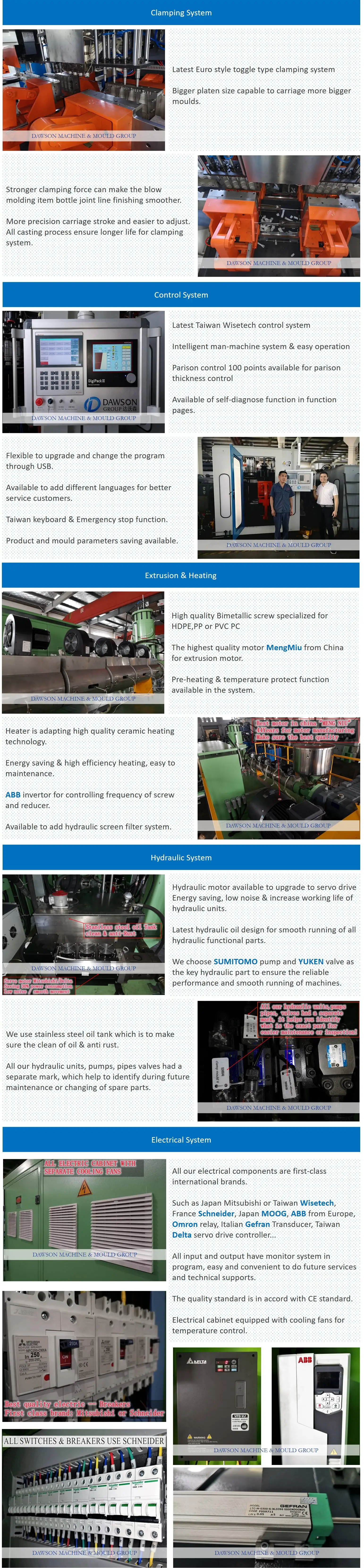

The whole blow molding machine is equipped with a bilingual operation panel. This is a game - changing feature that caters to a global user base. Whether the operators are in North America, Europe, or Asia, they can easily switch between languages, ensuring that every instruction and function on the panel is clearly understood. This eliminates language - related barriers and enables a seamless operation process, regardless of the operator's native language.

In addition, the machine is outfitted with automatic configurations sourced from world - famous brands. These components are known for their reliability, durability, and high - performance capabilities. Brands renowned for their precision engineering and cutting - edge technology contribute to the overall excellence of the DSB65/75.

Thanks to these top - notch components, the machine offers the distinct advantage of simple operation. Even for those new to blow molding technology, the intuitive design of the control panel and the well - integrated automatic systems make it easy to learn and operate. With just a few simple steps, operators can start the production process, adjust parameters, and monitor the manufacturing progress.

The high - level automation of the DSB65/75 is another remarkable feature. From the precise extrusion of the plastic material to the formation of the parison, the blowing process, and finally the ejection of the finished product, the machine can perform these tasks in a highly automated manner. This not only boosts production efficiency but also guarantees consistent product quality. With reduced human intervention, the risk of errors and variations in product quality is minimized, resulting in a high - yield of uniformly excellent plastic products.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |

The Extrusion Blow Molding Machine DSB65/75 represents a pinnacle of advanced manufacturing technology in the field of plastic processing. This state - of - the - art machine is designed with precision and versatility in mind, making it an ideal choice for a wide range of plastic product manufacturing needs.

It is highly suitable for the production of an extensive array of plastic items. When it comes to plastic bottles, it can craft everything from small - sized, 50ml bottles that are commonly used for storing essential oils, sample - sized cosmetics, or single - use medications, to larger 5L bottles which find applications in the beverage industry for packaging juices, water, or even in the industrial sector for storing chemicals and cleaning agents.

For jars, the DSB65/75 can create various styles, whether it's the small, delicate jars for facial creams and ointments or the more robust ones for storing food products like jams, honey, and pickles. These jars are produced with high - quality finishes, ensuring both aesthetic appeal and excellent functionality.

In the realm of small containers, this machine proves its mettle. It can manufacture containers for storing office supplies such as glue, correction fluid, and small stationery items, as well as containers for household use, like those for storing spices, small hardware, or craft materials.

Moreover, when it comes to jerrycans, the DSB65/75 is capable of producing them in the 50ml - 5L range. These jerrycans are perfect for storing and transporting fuels for small - scale machinery, water for outdoor activities, or other liquids in agricultural and DIY settings.

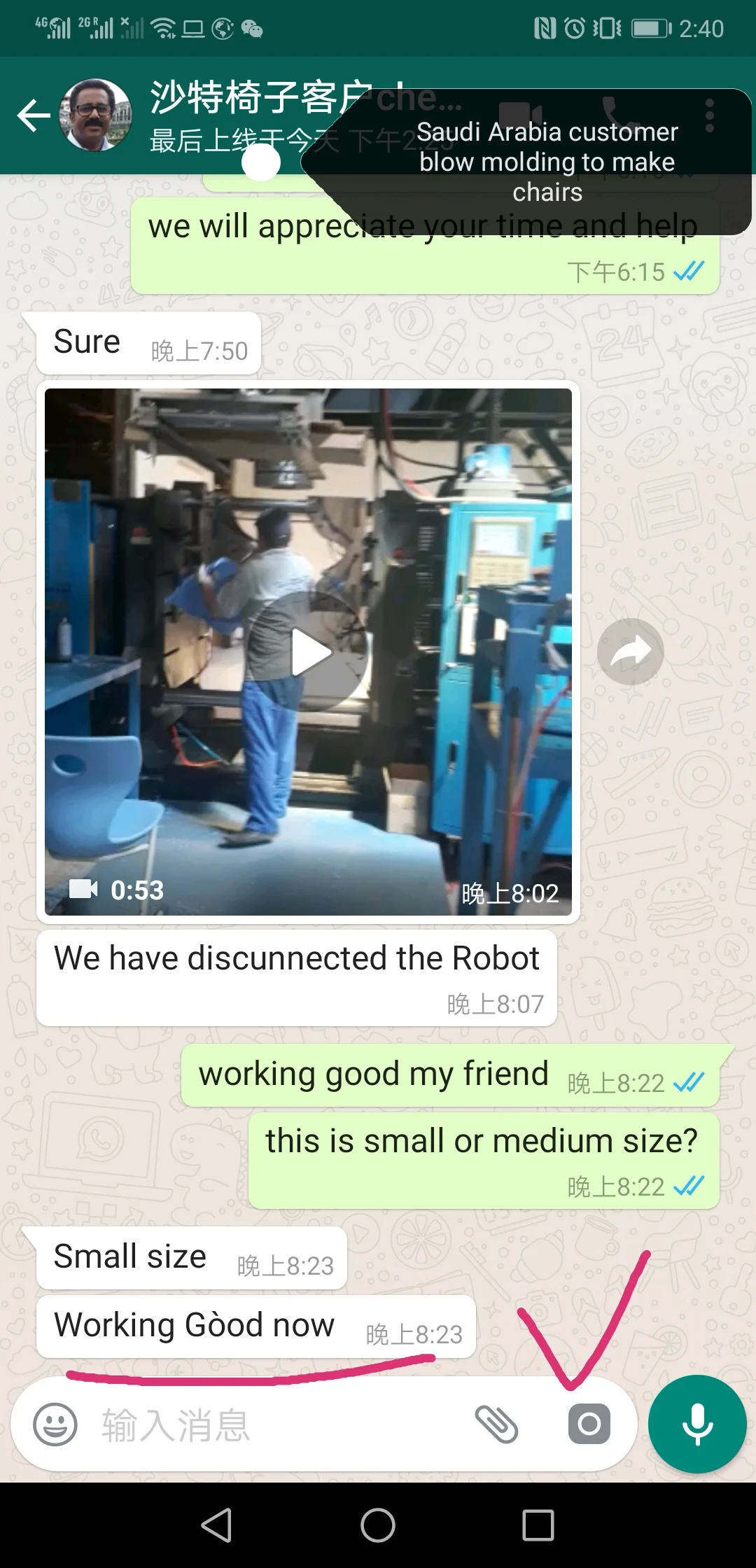

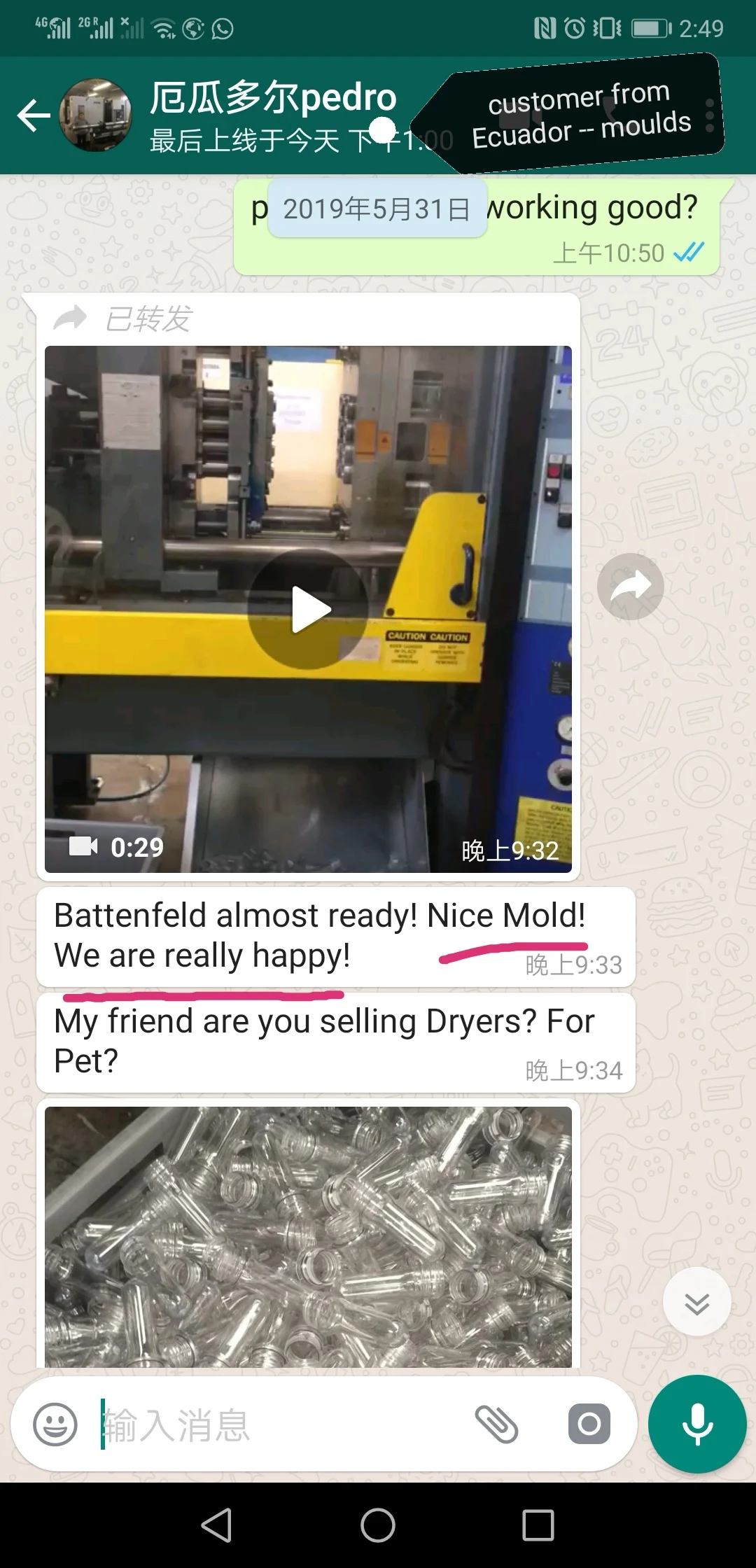

The whole blow molding machine is equipped with a bilingual operation panel. This is a game - changing feature that caters to a global user base. Whether the operators are in North America, Europe, or Asia, they can easily switch between languages, ensuring that every instruction and function on the panel is clearly understood. This eliminates language - related barriers and enables a seamless operation process, regardless of the operator's native language.

In addition, the machine is outfitted with automatic configurations sourced from world - famous brands. These components are known for their reliability, durability, and high - performance capabilities. Brands renowned for their precision engineering and cutting - edge technology contribute to the overall excellence of the DSB65/75.

Thanks to these top - notch components, the machine offers the distinct advantage of simple operation. Even for those new to blow molding technology, the intuitive design of the control panel and the well - integrated automatic systems make it easy to learn and operate. With just a few simple steps, operators can start the production process, adjust parameters, and monitor the manufacturing progress.

The high - level automation of the DSB65/75 is another remarkable feature. From the precise extrusion of the plastic material to the formation of the parison, the blowing process, and finally the ejection of the finished product, the machine can perform these tasks in a highly automated manner. This not only boosts production efficiency but also guarantees consistent product quality. With reduced human intervention, the risk of errors and variations in product quality is minimized, resulting in a high - yield of uniformly excellent plastic products.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |