- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ISB800-AN

DAWSON

This machine is versatile and commonly used across various industries for producing a wide range of products. It is perfect for manufacturing 10-1000 ml PET bottles for cosmetics, milk, sports water, pharmaceuticals, and even packaging for PC bottles, red wine cups, and LED lampshades. Its ability to produce these products with high precision and efficiency, combined with a high degree of automation, makes it the ideal choice for companies seeking reliable and cost-effective packaging solutions. The machine ensures not only uniformity in product quality but also optimizes production time, making it a key asset for manufacturers in different sectors.

|  |

Technical Parameters

| Model | ISB 800-3 | |

| Injection Part | ||

| Screw Diameter | 40mm | |

| Screw L/D Ratio | 20.5:1 | |

| Screw Speed | 0-190RPM | |

| Theoretical Injection Capacity | 238cm3 | |

| Injection Pressure | 174Mpa | |

| Max. Hydraulic Pressure | 140Kg/cm | |

| The Actual Injection Quantity(PS): | 225g(ps)/8Oz | |

| Screw Stroke: | 190Mm | |

| Clamping Part | ||

| Blow Clamping Force: | 80Kn | |

| Clamp Tonnage: | 400Kn | |

| Wheel Diameter: | 800mm | |

| Max. Height of Bottle: | ISB:145/IB:140 | |

| Open Vertical Mode Trip: | 430mm | |

| Others | ||

| Max. Pump Pressure: | 16Mpa | |

| Motor Oil: | 18.5Kw | |

| Electric Power: | 12.2Kw | |

| Oil Tank: | 400L | |

| Overall Dimension(L*W*H): | 3.8m*1.45m*3.0m | |

| Weight: | 5000kg | |

Machine Advantages

One Step Injection Stretch blow moulding machine decrease the convey cost and avoid the second contamination, special for food and pharmaceutical company. For example, to transit the 19g 500ml bottle, if the 1m³ trunk used, it can load 1024 bottles, or 9280 preform, but if buy the raw material that can produce 56421 bottles. The logistic cost of material comparing with transiting bottles can be reduced by 98.2%; Comparing with the cost of transiting preform, the cost can be reduced by 83.6%.

| Molding | Process | Structure | Manpower/Energy /Space | Product Quality |

| Dawson One-step Injection Stretch Blow Molding Machine | From preform to product in one machine | One machine | Little | Not affect by damp and less pollution; Various kinds of shape |

| Other machine | Injection and blow molding are two separated process | 1.Injection molding machine 2.Preform transiting machine 3.Reheating, stretch and off-moulding machine | More | Easy affect by damp and polluted; Singleness shape |

|  |

|  |

| Machine Model | Applications | ||

| ISB800 | PC, PS,PMMA lamp cover, LED light lampshade,Christmas flash light, garden and street light. | ||

| PET high transparent bottle(thinner wall), cosmetic bottle 10ml to 500ml, PET wide neck jar, PET pharmaceutical bottle. | |||

| PP high transparent bottle, baby feeding bottle, sport bottle. | |||

| PCTG, Tritan drinking water bottle, sport bottle. | |||

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

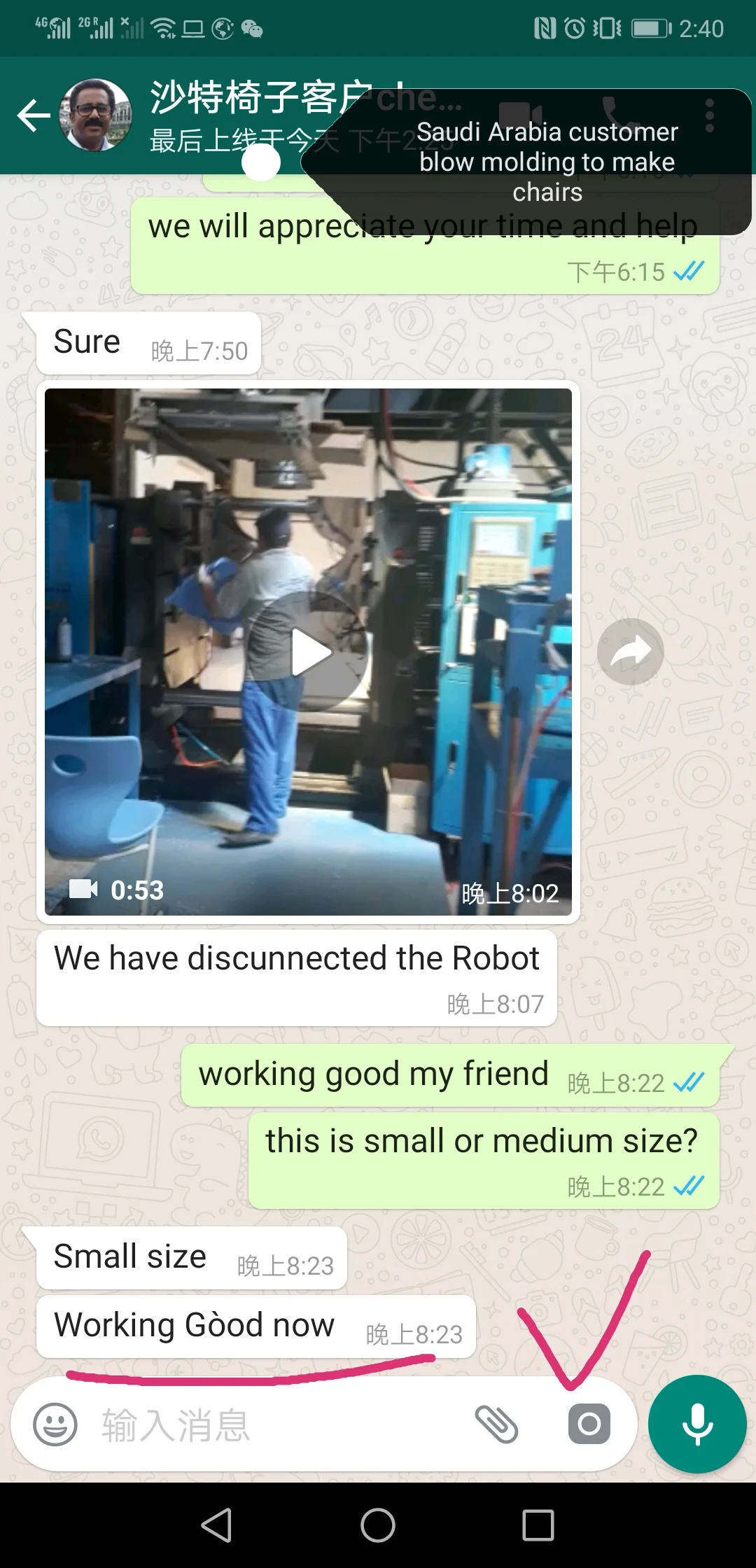

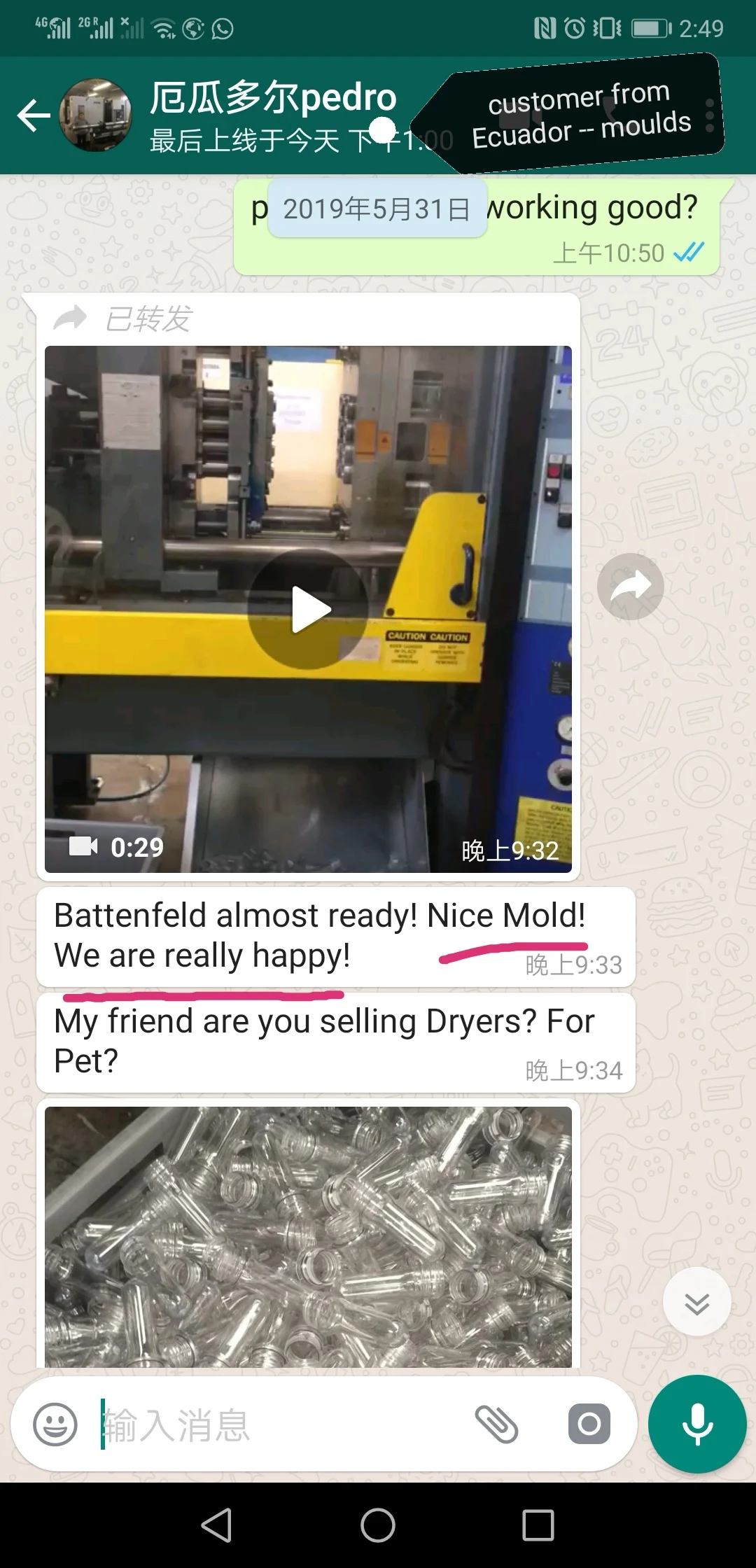

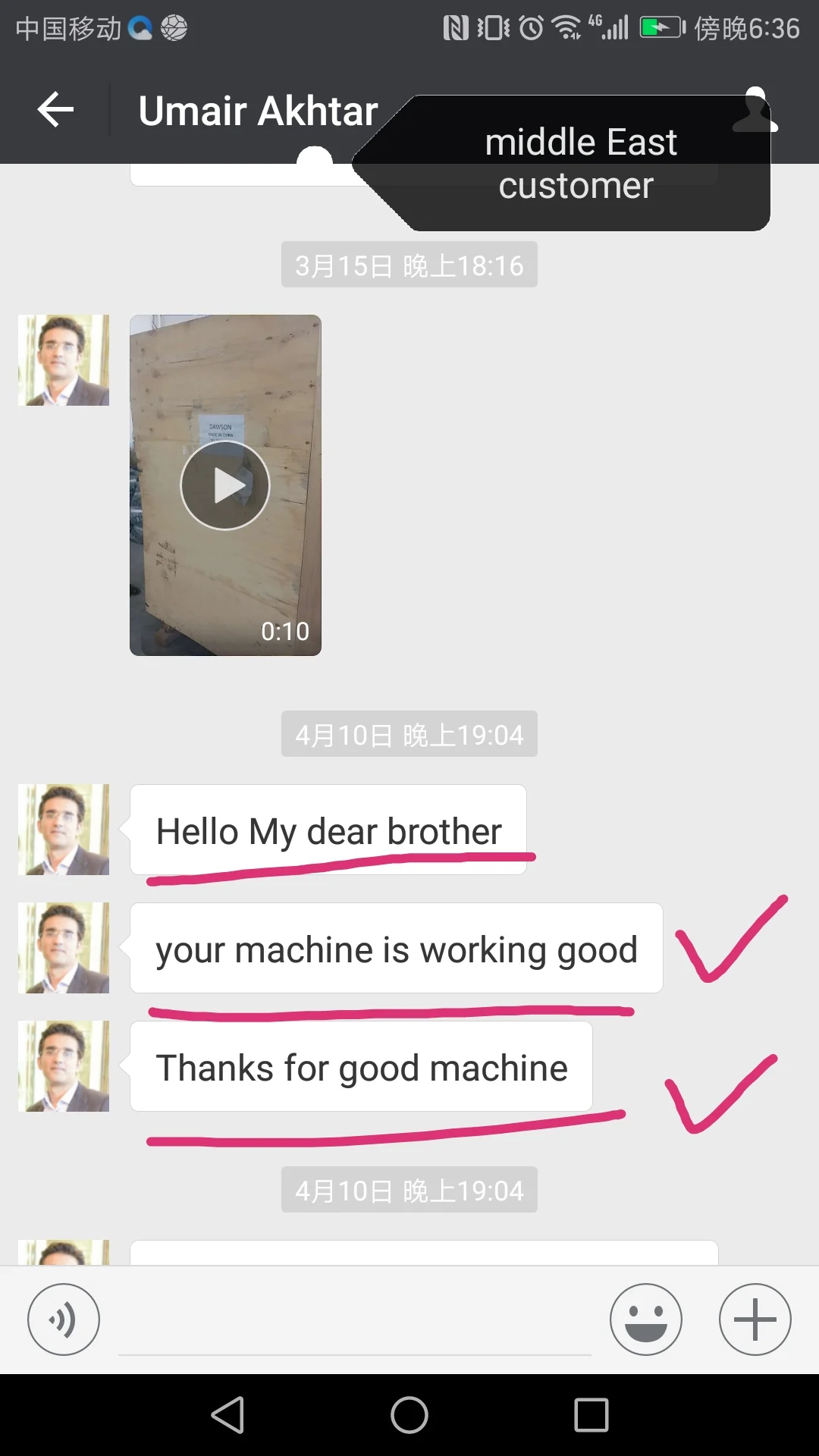

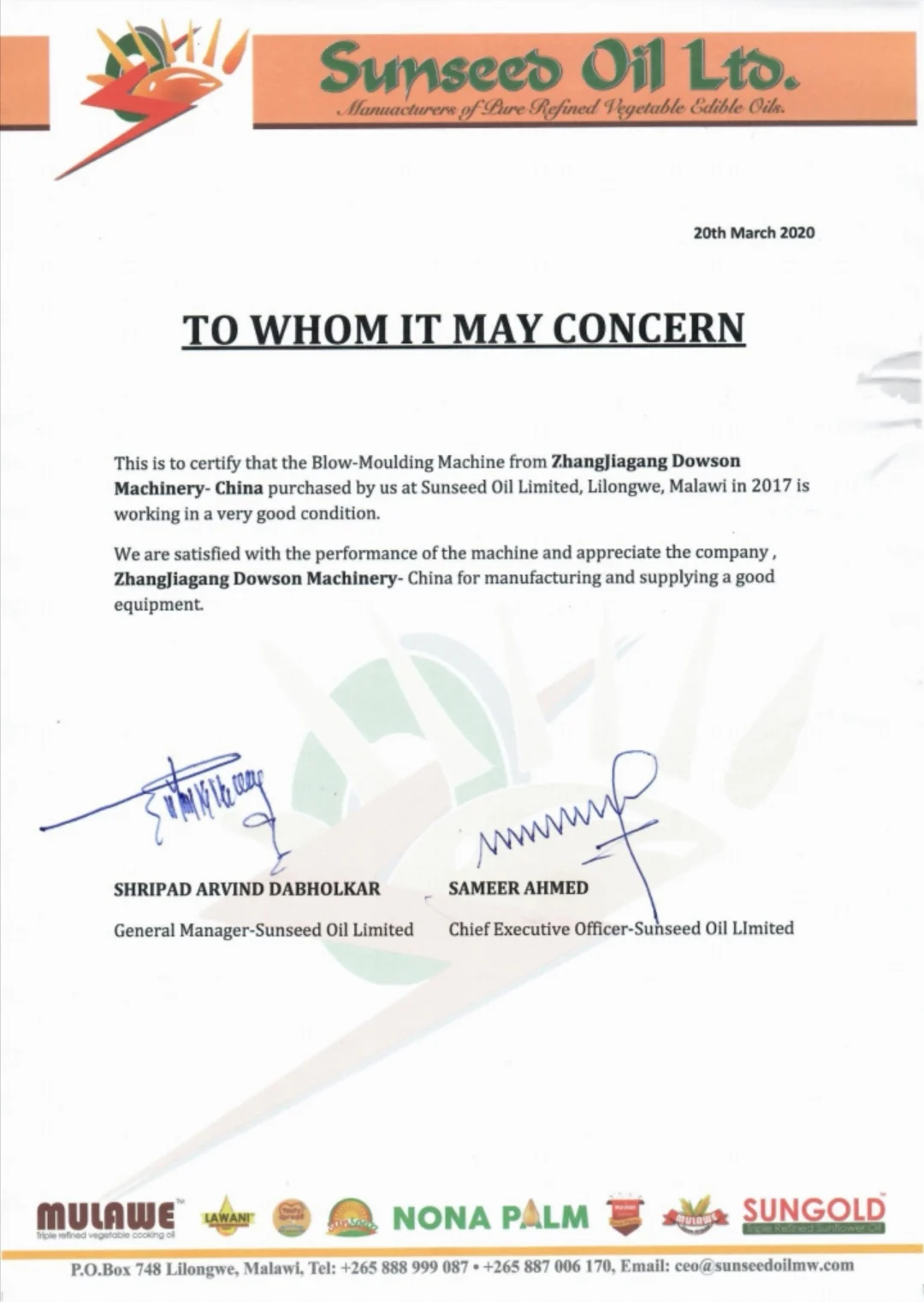

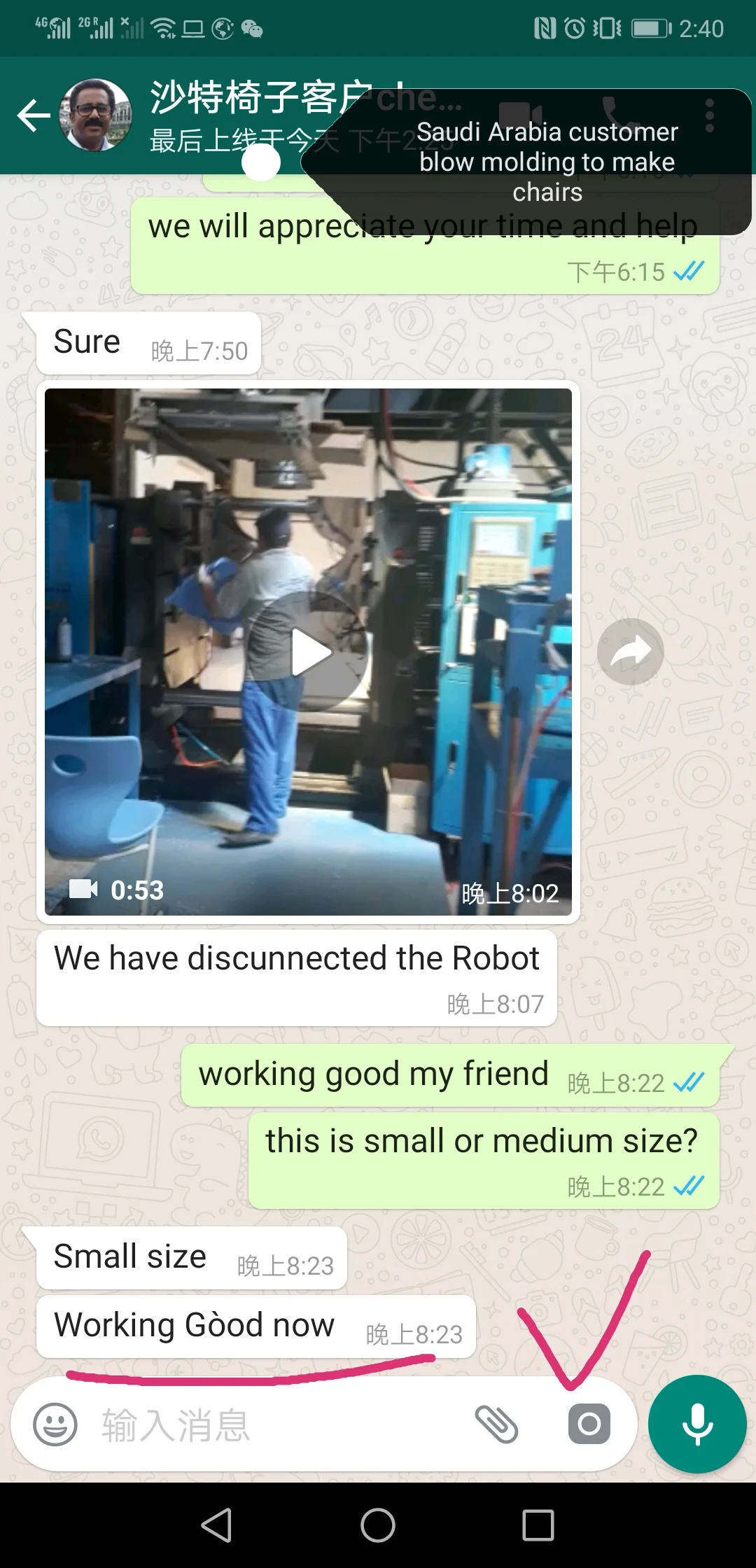

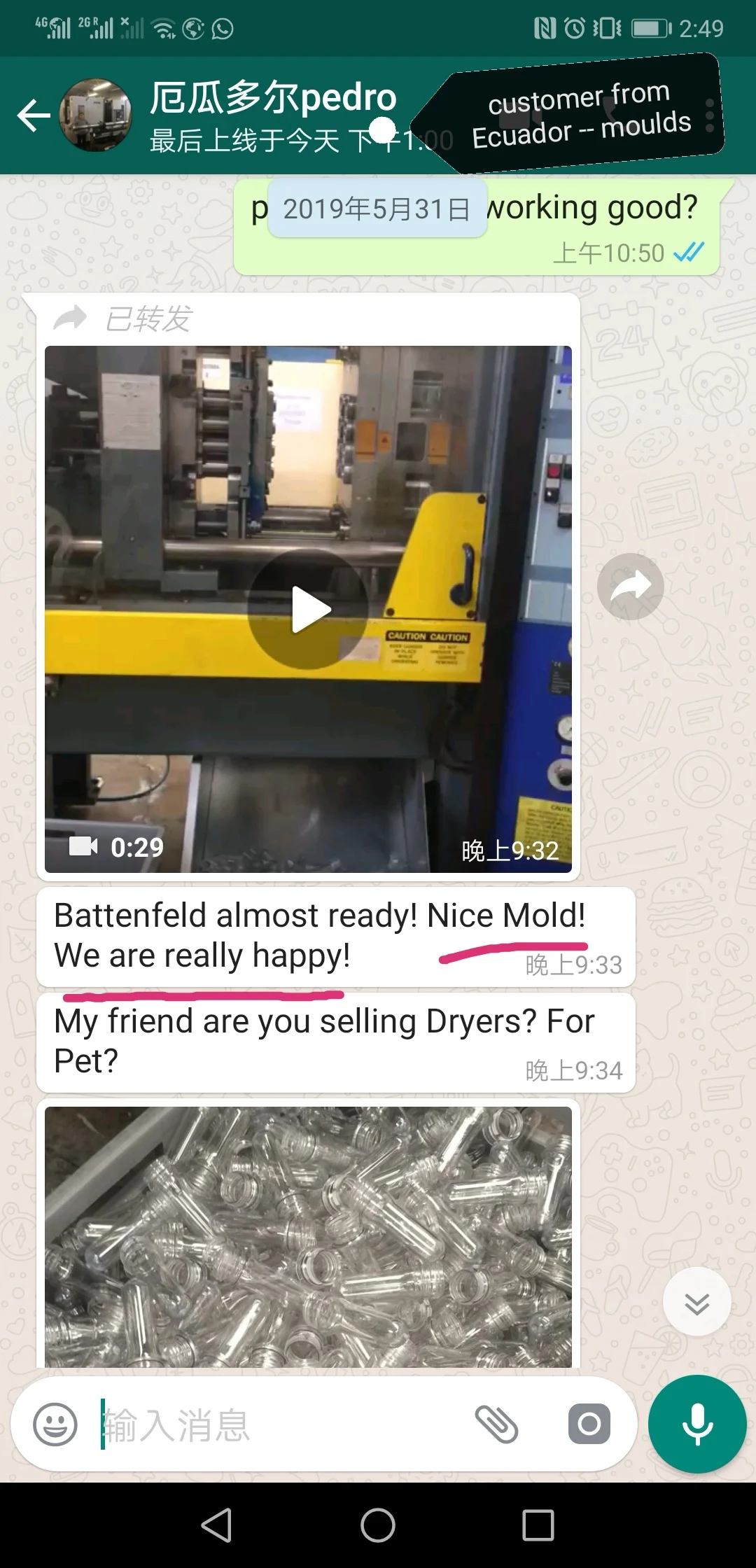

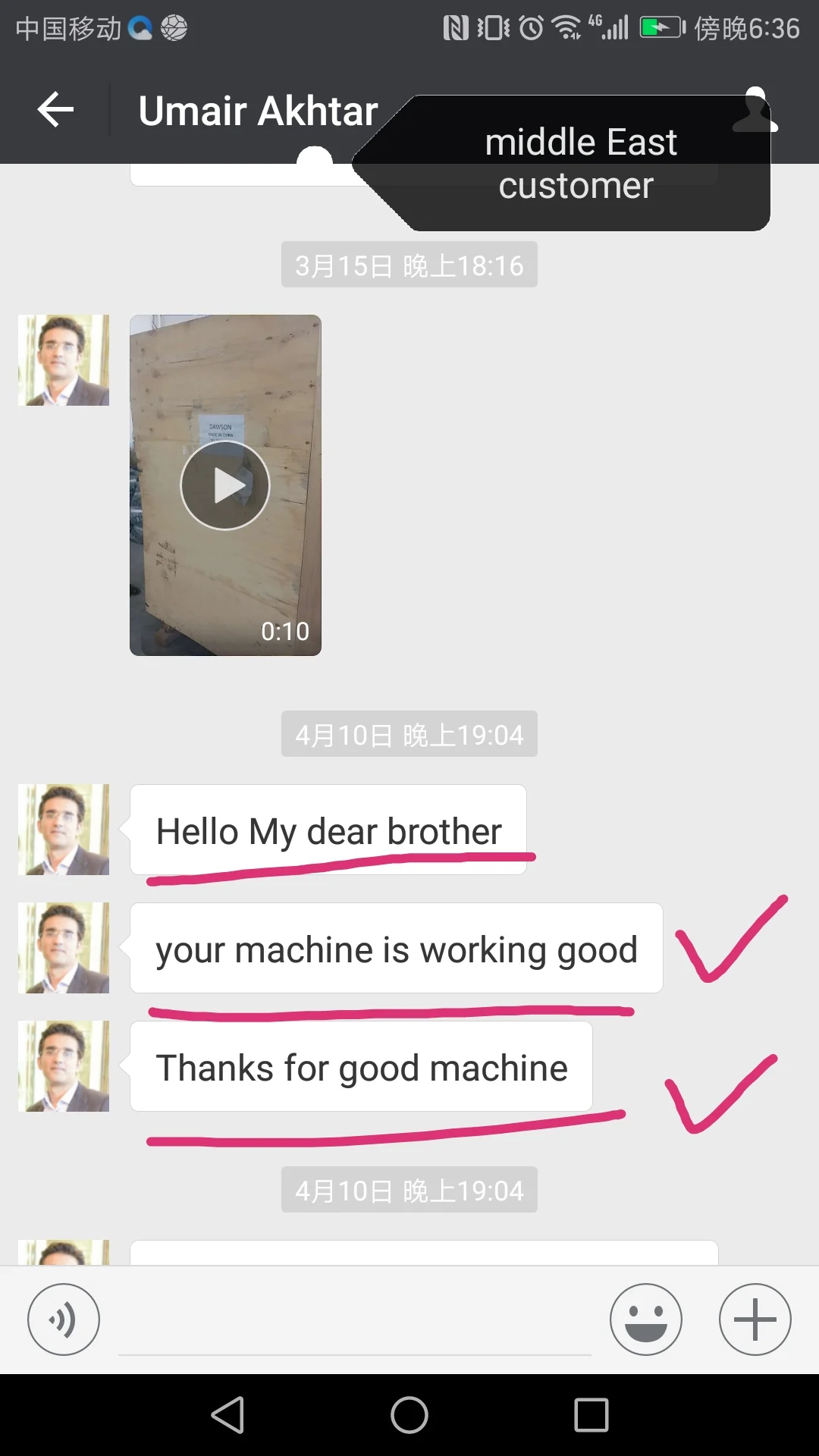

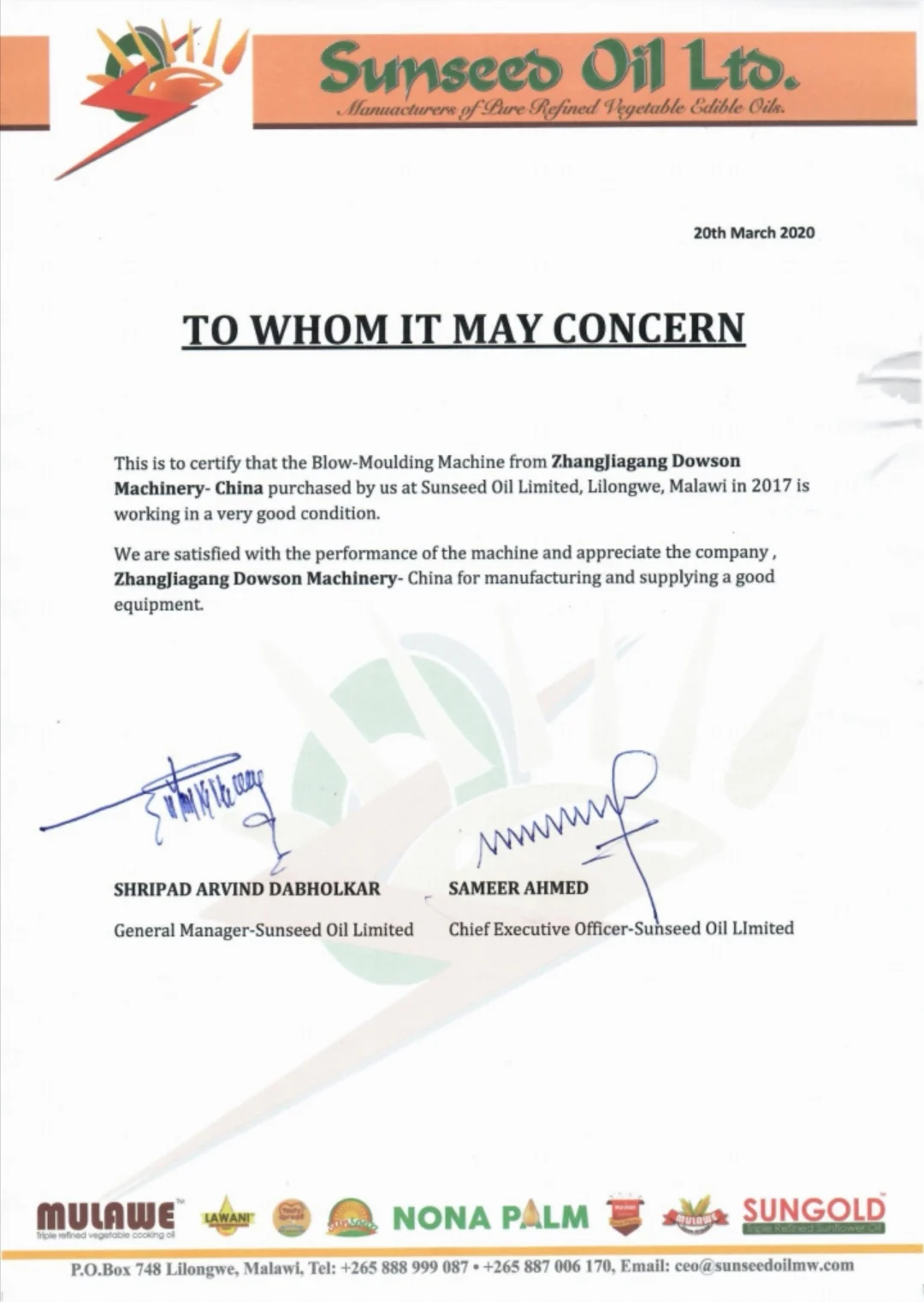

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |

This machine is versatile and commonly used across various industries for producing a wide range of products. It is perfect for manufacturing 10-1000 ml PET bottles for cosmetics, milk, sports water, pharmaceuticals, and even packaging for PC bottles, red wine cups, and LED lampshades. Its ability to produce these products with high precision and efficiency, combined with a high degree of automation, makes it the ideal choice for companies seeking reliable and cost-effective packaging solutions. The machine ensures not only uniformity in product quality but also optimizes production time, making it a key asset for manufacturers in different sectors.

|  |

Technical Parameters

| Model | ISB 800-3 | |

| Injection Part | ||

| Screw Diameter | 40mm | |

| Screw L/D Ratio | 20.5:1 | |

| Screw Speed | 0-190RPM | |

| Theoretical Injection Capacity | 238cm3 | |

| Injection Pressure | 174Mpa | |

| Max. Hydraulic Pressure | 140Kg/cm | |

| The Actual Injection Quantity(PS): | 225g(ps)/8Oz | |

| Screw Stroke: | 190Mm | |

| Clamping Part | ||

| Blow Clamping Force: | 80Kn | |

| Clamp Tonnage: | 400Kn | |

| Wheel Diameter: | 800mm | |

| Max. Height of Bottle: | ISB:145/IB:140 | |

| Open Vertical Mode Trip: | 430mm | |

| Others | ||

| Max. Pump Pressure: | 16Mpa | |

| Motor Oil: | 18.5Kw | |

| Electric Power: | 12.2Kw | |

| Oil Tank: | 400L | |

| Overall Dimension(L*W*H): | 3.8m*1.45m*3.0m | |

| Weight: | 5000kg | |

Machine Advantages

One Step Injection Stretch blow moulding machine decrease the convey cost and avoid the second contamination, special for food and pharmaceutical company. For example, to transit the 19g 500ml bottle, if the 1m³ trunk used, it can load 1024 bottles, or 9280 preform, but if buy the raw material that can produce 56421 bottles. The logistic cost of material comparing with transiting bottles can be reduced by 98.2%; Comparing with the cost of transiting preform, the cost can be reduced by 83.6%.

| Molding | Process | Structure | Manpower/Energy /Space | Product Quality |

| Dawson One-step Injection Stretch Blow Molding Machine | From preform to product in one machine | One machine | Little | Not affect by damp and less pollution; Various kinds of shape |

| Other machine | Injection and blow molding are two separated process | 1.Injection molding machine 2.Preform transiting machine 3.Reheating, stretch and off-moulding machine | More | Easy affect by damp and polluted; Singleness shape |

|  |

|  |

| Machine Model | Applications | ||

| ISB800 | PC, PS,PMMA lamp cover, LED light lampshade,Christmas flash light, garden and street light. | ||

| PET high transparent bottle(thinner wall), cosmetic bottle 10ml to 500ml, PET wide neck jar, PET pharmaceutical bottle. | |||

| PP high transparent bottle, baby feeding bottle, sport bottle. | |||

| PCTG, Tritan drinking water bottle, sport bottle. | |||

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |