- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ISB800-AN

DAWSON

Injection Stretch Blow Molding Machine ISB800

This highly - efficient machine is designed with a sophisticated structure that features three distinct stations: the injection preform station, the blowing & stretch station, and the product release station. Each station plays a crucial role in the seamless production process, ensuring high - quality output.

After the preforms are created at the injection preform station, they are transferred to the next stage - the blowing & stretch station. This is where the magic really happens. The plate on which the preforms are placed rotates, smoothly moving the preforms to the blowing & stretch station. One of the remarkable features of this machine is that it utilizes the preforms' own residual heat for the blowing and stretching process. There is no need for any additional reheating during this crucial step. This energy - saving design not only reduces the overall production cost but also speeds up the manufacturing process. As the preforms reach the blowing & stretch station, compressed air is introduced into them.

Simultaneously, mechanical stretching mechanisms are activated. This combination of blowing and stretching forces the plastic preforms to expand and take on the final shape of the product, whether it's a bottle, a cup, or a lampshade.

Once the products have been successfully blown and stretched, they are ready for the final stage - the product release station. The plate continues its rotation, carrying the now - finished products to the release station. At this point, the products simply drop down from the molds, ready to be collected and further processed or packaged. This entire process operates in a fully automatically cycle rotation working mode.

This working mode brings a multitude of advantages. Firstly, there is no need to purchase pre - made bottle preforms from external suppliers. This not only saves costs but also gives manufacturers full control over the production process from start to finish. Secondly, the machine is designed with waste - reduction in mind. The precise material - handling and manufacturing processes ensure that there is minimal waste generated, making it an environmentally friendly choice. The high degree of automation is another major plus. With a high - level of automation, the machine can operate continuously with minimal human intervention. This not only increases production efficiency but also reduces the risk of human - error, ensuring that the finished products are of consistently high quality. And indeed, the finished products are characterized by their smooth and beautiful appearance. The surfaces of the products are free from blemishes, and the shapes are precisely formed, meeting the high - standard requirements of various industries.

|  |

Technical Parameters

| Model | ISB 800-3 | |

| Injection Part | ||

| Screw Diameter | 40mm | |

| Screw L/D Ratio | 20.5:1 | |

| Screw Speed | 0-190RPM | |

| Theoretical Injection Capacity | 238cm3 | |

| Injection Pressure | 174Mpa | |

| Max. Hydraulic Pressure | 140Kg/cm | |

| The Actual Injection Quantity(PS): | 225g(ps)/8Oz | |

| Screw Stroke: | 190Mm | |

| Clamping Part | ||

| Blow Clamping Force: | 80Kn | |

| Clamp Tonnage: | 400Kn | |

| Wheel Diameter: | 800mm | |

| Max. Height of Bottle: | ISB:145/IB:140 | |

| Open Vertical Mode Trip: | 430mm | |

| Others | ||

| Max. Pump Pressure: | 16Mpa | |

| Motor Oil: | 18.5Kw | |

| Electric Power: | 12.2Kw | |

| Oil Tank: | 400L | |

| Overall Dimension(L*W*H): | 3.8m*1.45m*3.0m | |

| Weight: | 5000kg | |

Machine Advantages

One Step Injection Stretch blow moulding machine decrease the convey cost and avoid the second contamination, special for food and pharmaceutical company. For example, to transit the 19g 500ml bottle, if the 1m³ trunk used, it can load 1024 bottles, or 9280 preform, but if buy the raw material that can produce 56421 bottles. The logistic cost of material comparing with transiting bottles can be reduced by 98.2%; Comparing with the cost of transiting preform, the cost can be reduced by 83.6%.

| Molding | Process | Structure | Manpower/Energy /Space | Product Quality |

| Dawson One-step Injection Stretch Blow Molding Machine | From preform to product in one machine | One machine | Little | Not affect by damp and less pollution; Various kinds of shape |

| Other machine | Injection and blow molding are two separated process | 1.Injection molding machine 2.Preform transiting machine 3.Reheating, stretch and off-moulding machine | More | Easy affect by damp and polluted; Singleness shape |

|  |

|  |

| Machine Model | Applications | ||

| ISB800 | PC, PS,PMMA lamp cover, LED light lampshade,Christmas flash light, garden and street light. | ||

| PET high transparent bottle(thinner wall), cosmetic bottle 10ml to 500ml, PET wide neck jar, PET pharmaceutical bottle. | |||

| PP high transparent bottle, baby feeding bottle, sport bottle. | |||

| PCTG, Tritan drinking water bottle, sport bottle. | |||

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

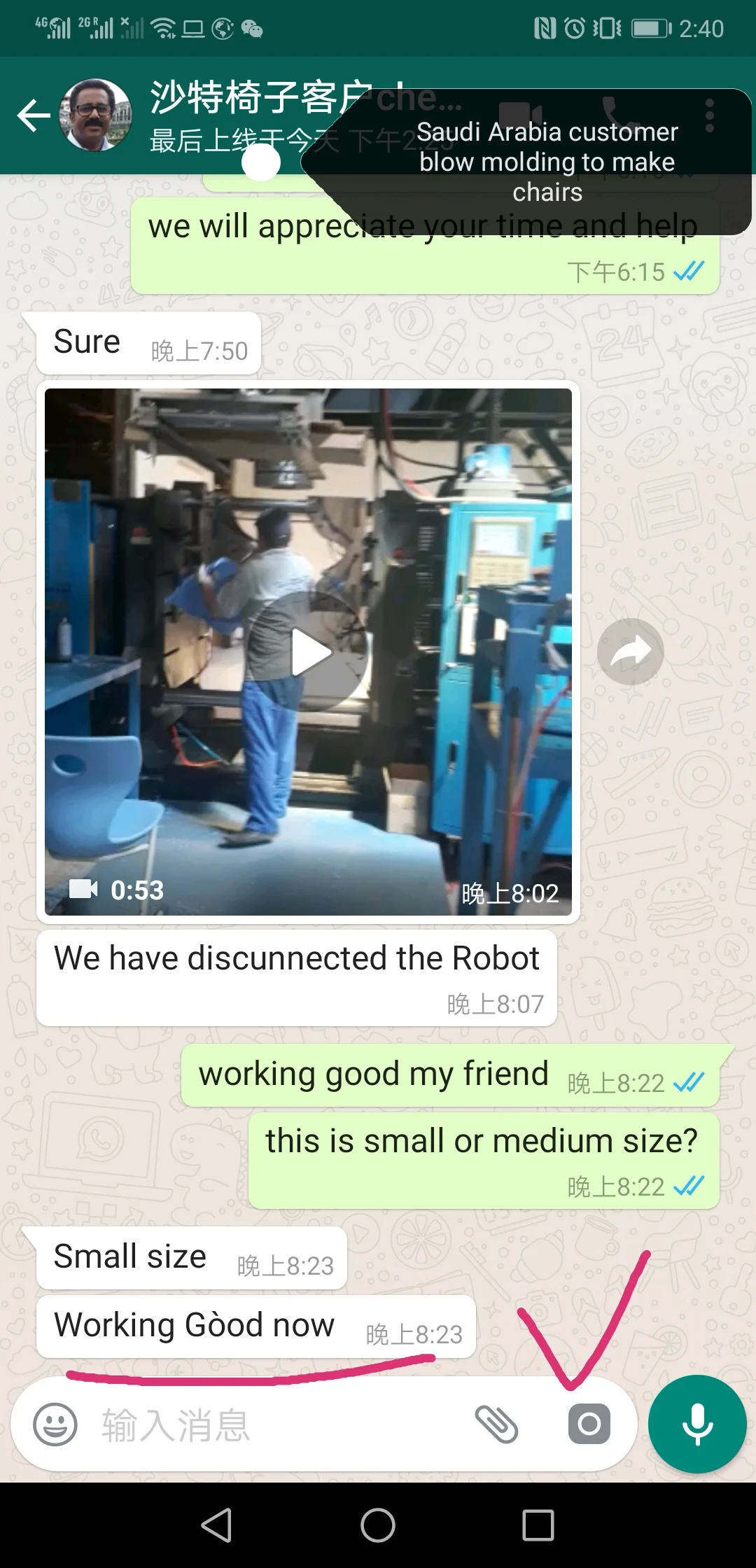

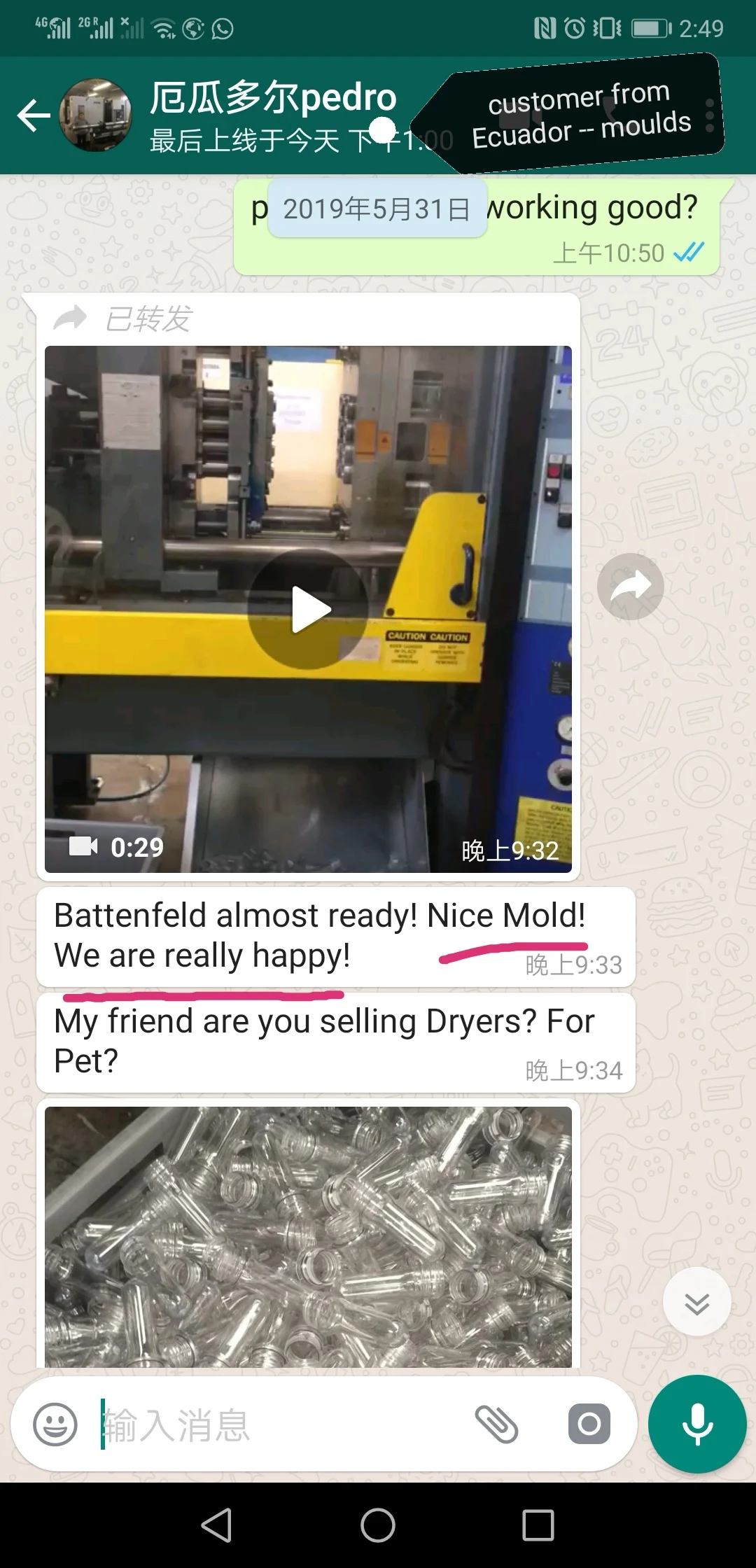

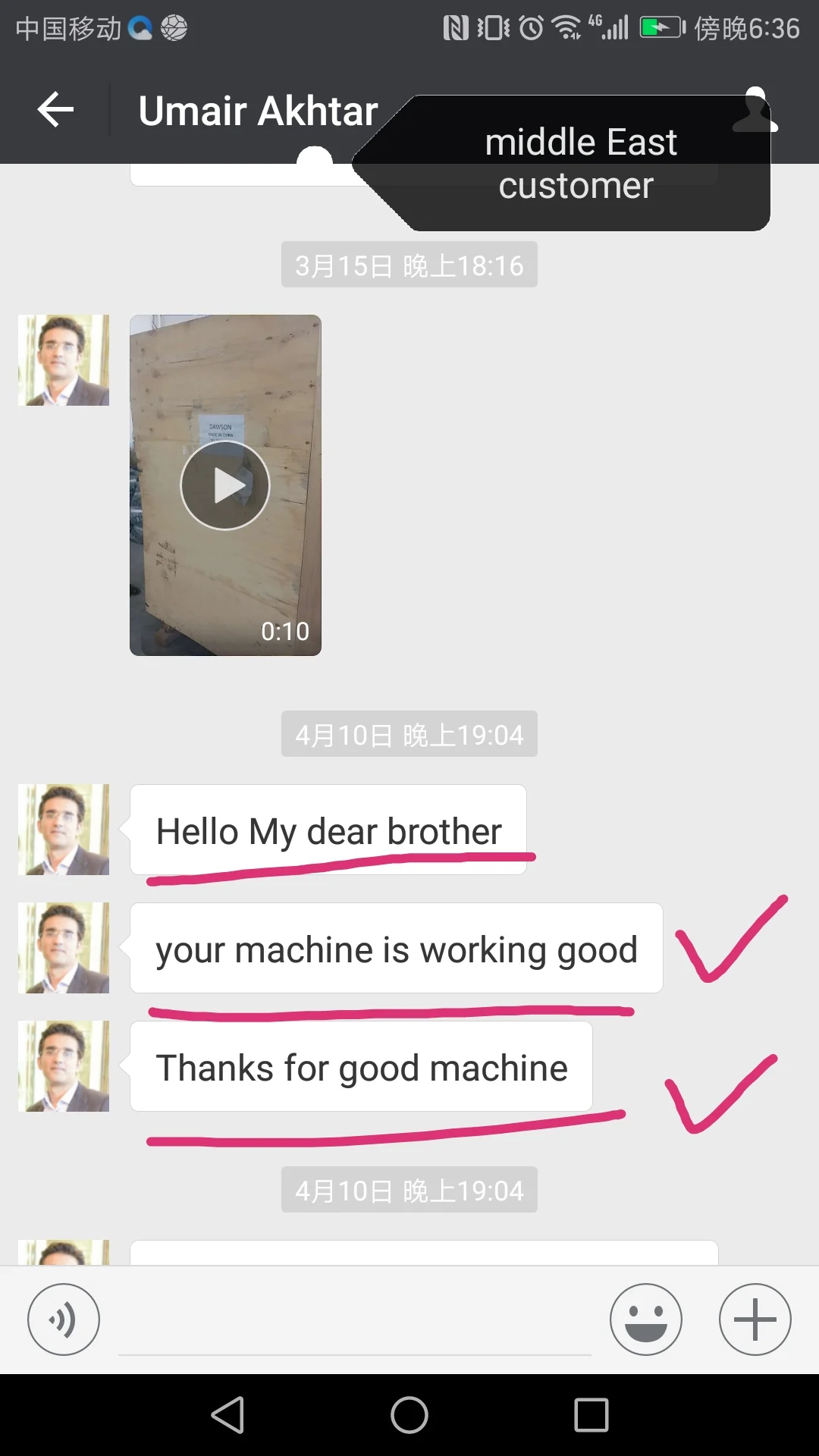

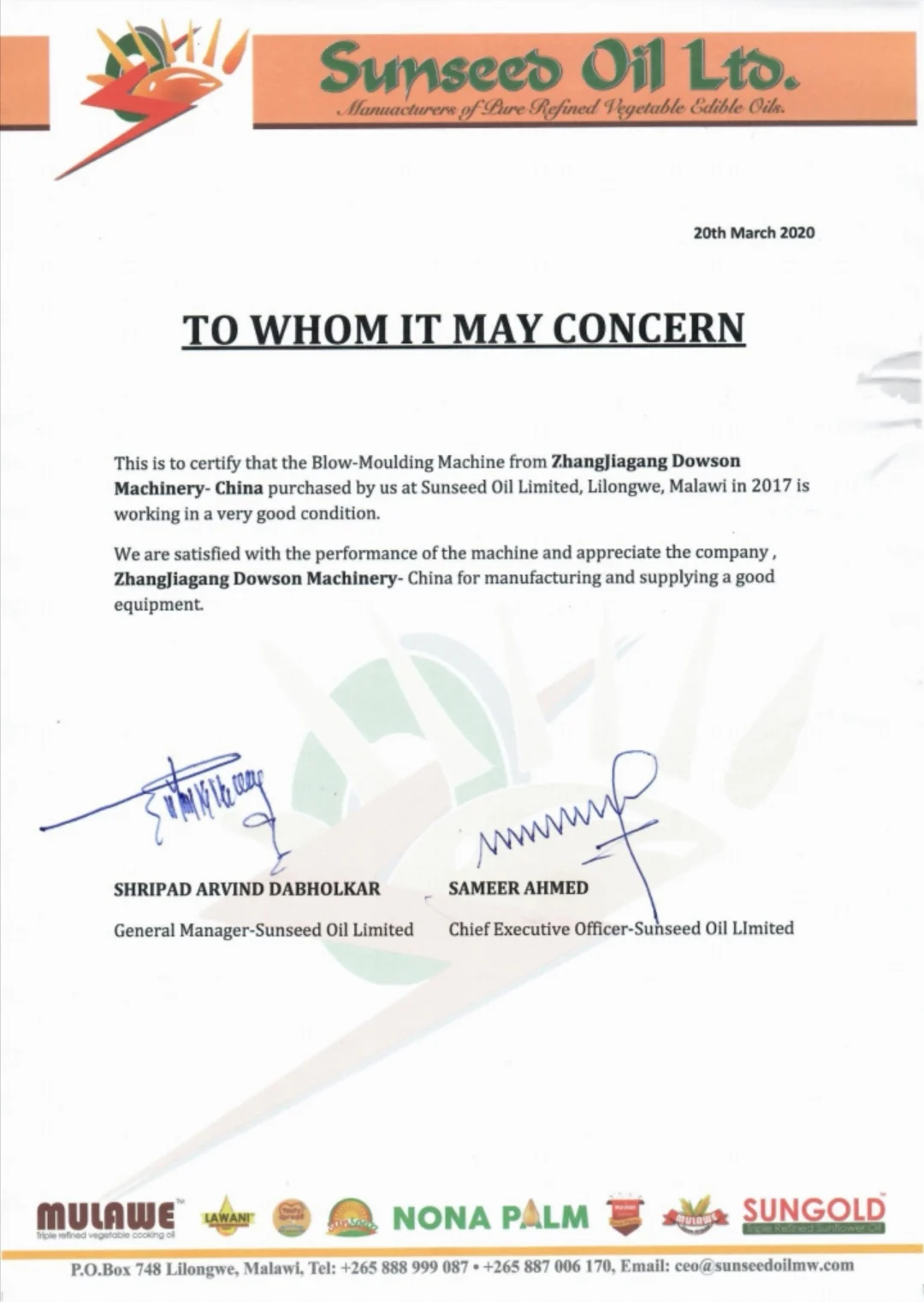

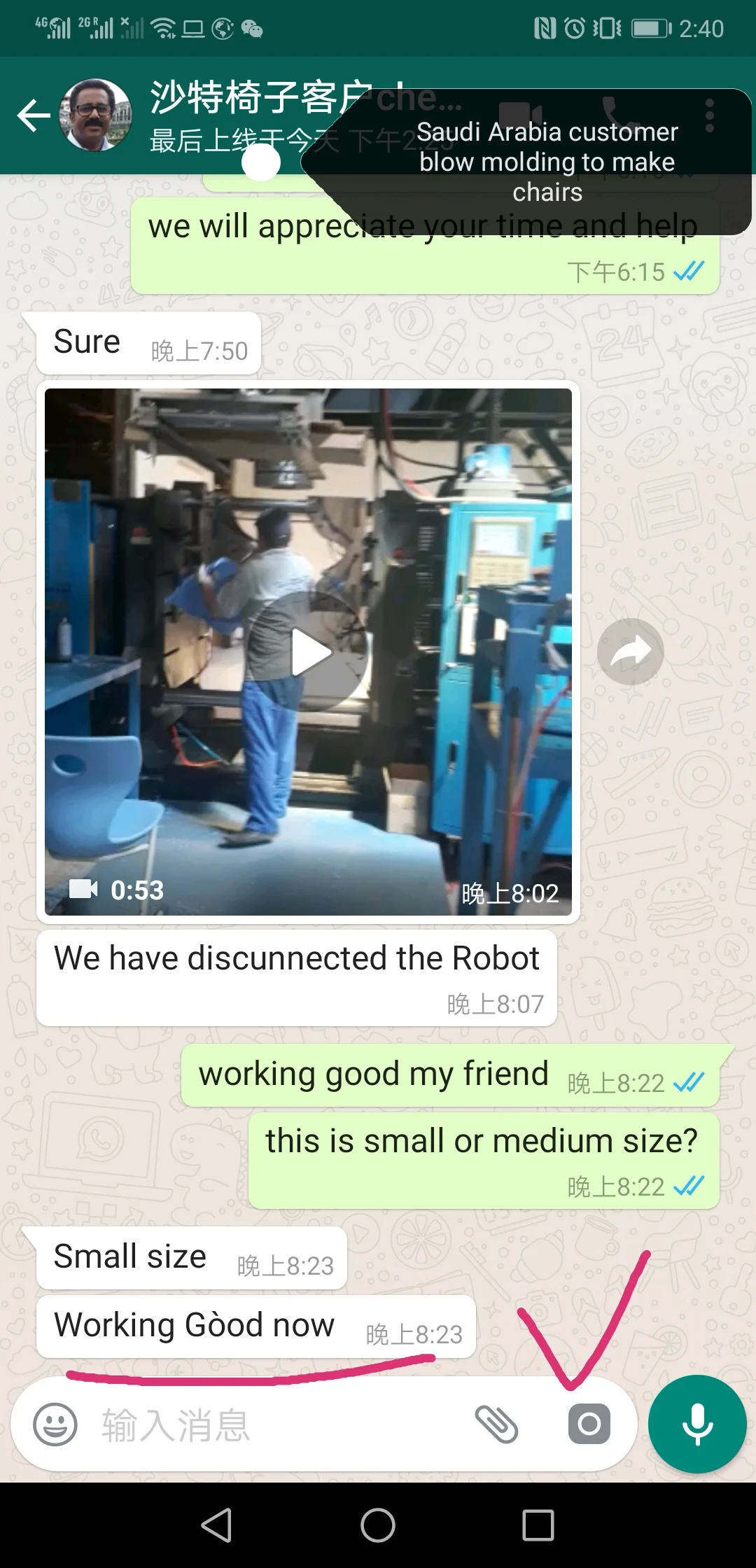

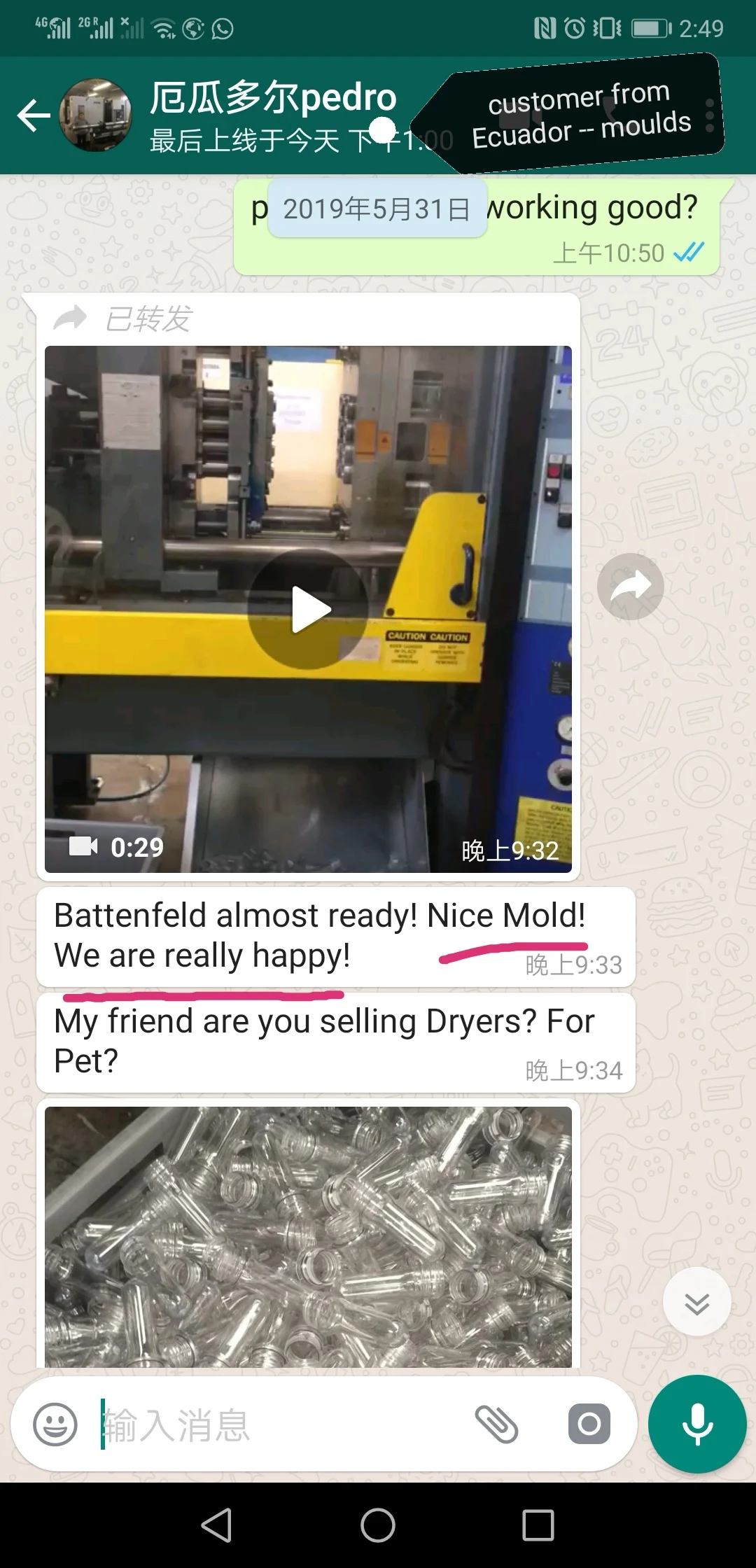

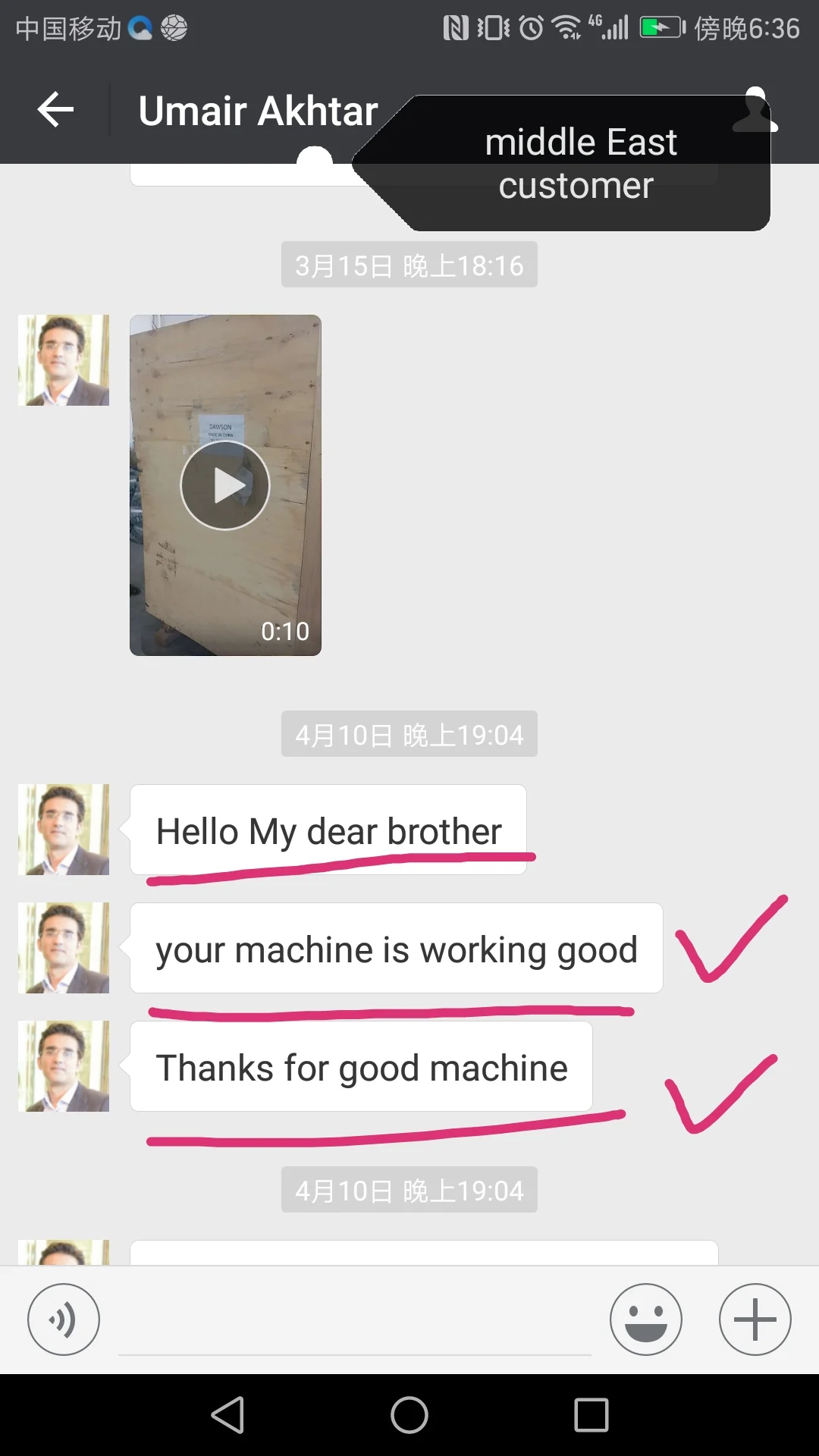

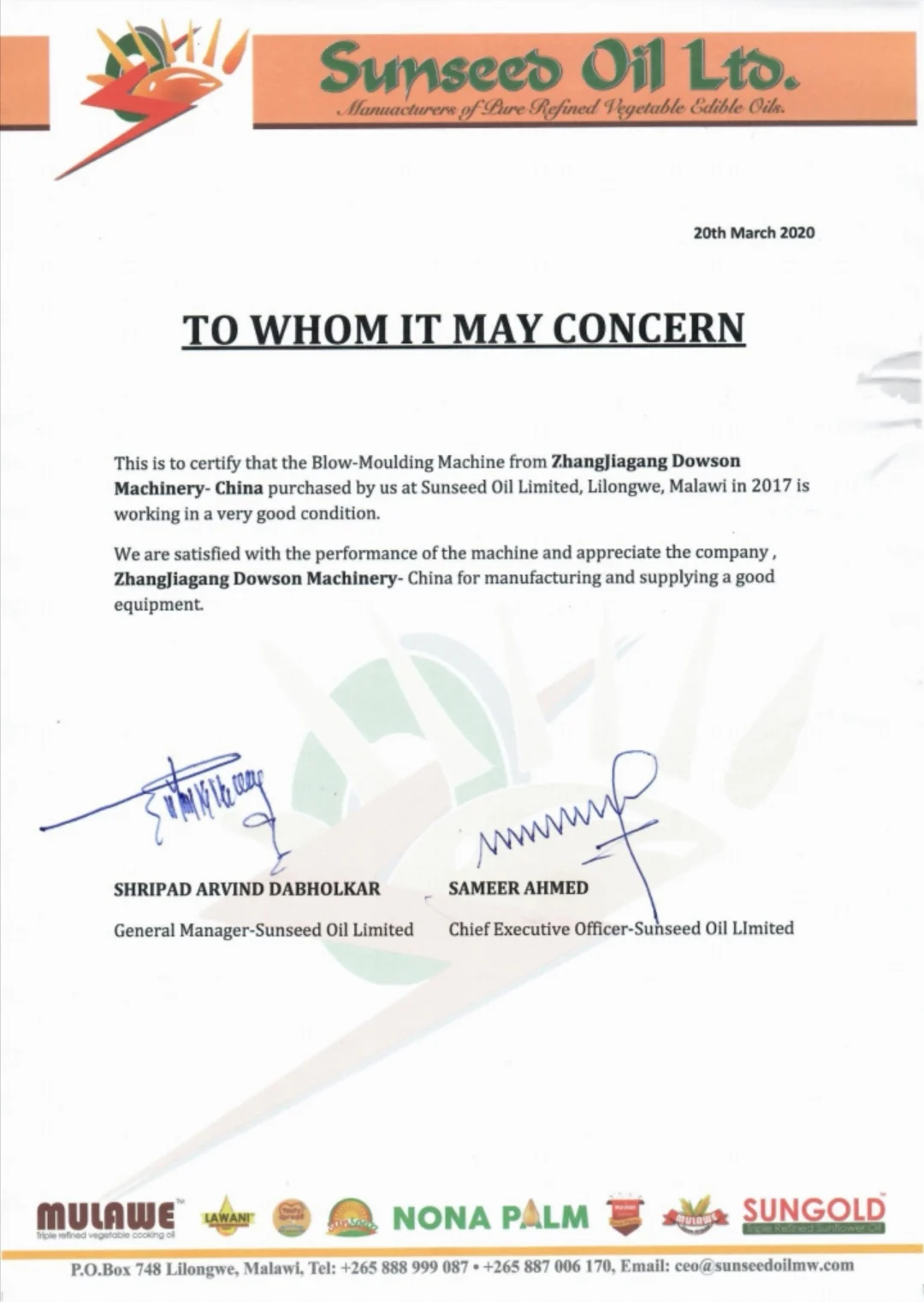

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |

Injection Stretch Blow Molding Machine ISB800

This highly - efficient machine is designed with a sophisticated structure that features three distinct stations: the injection preform station, the blowing & stretch station, and the product release station. Each station plays a crucial role in the seamless production process, ensuring high - quality output.

After the preforms are created at the injection preform station, they are transferred to the next stage - the blowing & stretch station. This is where the magic really happens. The plate on which the preforms are placed rotates, smoothly moving the preforms to the blowing & stretch station. One of the remarkable features of this machine is that it utilizes the preforms' own residual heat for the blowing and stretching process. There is no need for any additional reheating during this crucial step. This energy - saving design not only reduces the overall production cost but also speeds up the manufacturing process. As the preforms reach the blowing & stretch station, compressed air is introduced into them.

Simultaneously, mechanical stretching mechanisms are activated. This combination of blowing and stretching forces the plastic preforms to expand and take on the final shape of the product, whether it's a bottle, a cup, or a lampshade.

Once the products have been successfully blown and stretched, they are ready for the final stage - the product release station. The plate continues its rotation, carrying the now - finished products to the release station. At this point, the products simply drop down from the molds, ready to be collected and further processed or packaged. This entire process operates in a fully automatically cycle rotation working mode.

This working mode brings a multitude of advantages. Firstly, there is no need to purchase pre - made bottle preforms from external suppliers. This not only saves costs but also gives manufacturers full control over the production process from start to finish. Secondly, the machine is designed with waste - reduction in mind. The precise material - handling and manufacturing processes ensure that there is minimal waste generated, making it an environmentally friendly choice. The high degree of automation is another major plus. With a high - level of automation, the machine can operate continuously with minimal human intervention. This not only increases production efficiency but also reduces the risk of human - error, ensuring that the finished products are of consistently high quality. And indeed, the finished products are characterized by their smooth and beautiful appearance. The surfaces of the products are free from blemishes, and the shapes are precisely formed, meeting the high - standard requirements of various industries.

|  |

Technical Parameters

| Model | ISB 800-3 | |

| Injection Part | ||

| Screw Diameter | 40mm | |

| Screw L/D Ratio | 20.5:1 | |

| Screw Speed | 0-190RPM | |

| Theoretical Injection Capacity | 238cm3 | |

| Injection Pressure | 174Mpa | |

| Max. Hydraulic Pressure | 140Kg/cm | |

| The Actual Injection Quantity(PS): | 225g(ps)/8Oz | |

| Screw Stroke: | 190Mm | |

| Clamping Part | ||

| Blow Clamping Force: | 80Kn | |

| Clamp Tonnage: | 400Kn | |

| Wheel Diameter: | 800mm | |

| Max. Height of Bottle: | ISB:145/IB:140 | |

| Open Vertical Mode Trip: | 430mm | |

| Others | ||

| Max. Pump Pressure: | 16Mpa | |

| Motor Oil: | 18.5Kw | |

| Electric Power: | 12.2Kw | |

| Oil Tank: | 400L | |

| Overall Dimension(L*W*H): | 3.8m*1.45m*3.0m | |

| Weight: | 5000kg | |

Machine Advantages

One Step Injection Stretch blow moulding machine decrease the convey cost and avoid the second contamination, special for food and pharmaceutical company. For example, to transit the 19g 500ml bottle, if the 1m³ trunk used, it can load 1024 bottles, or 9280 preform, but if buy the raw material that can produce 56421 bottles. The logistic cost of material comparing with transiting bottles can be reduced by 98.2%; Comparing with the cost of transiting preform, the cost can be reduced by 83.6%.

| Molding | Process | Structure | Manpower/Energy /Space | Product Quality |

| Dawson One-step Injection Stretch Blow Molding Machine | From preform to product in one machine | One machine | Little | Not affect by damp and less pollution; Various kinds of shape |

| Other machine | Injection and blow molding are two separated process | 1.Injection molding machine 2.Preform transiting machine 3.Reheating, stretch and off-moulding machine | More | Easy affect by damp and polluted; Singleness shape |

|  |

|  |

| Machine Model | Applications | ||

| ISB800 | PC, PS,PMMA lamp cover, LED light lampshade,Christmas flash light, garden and street light. | ||

| PET high transparent bottle(thinner wall), cosmetic bottle 10ml to 500ml, PET wide neck jar, PET pharmaceutical bottle. | |||

| PP high transparent bottle, baby feeding bottle, sport bottle. | |||

| PCTG, Tritan drinking water bottle, sport bottle. | |||

Professional Workshop

|  |

|  |

Company Profile

DAWSON will be your reliable friend in China, and we will always do our best to give you max support!

Customer Photos

|  |  |

|  |  |

|  |  |  |

|  |  |  |

Our Service

| FAQ |

| Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's DAWSON's advantage? DAWSON provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. DAWSON will be your reliable friend in China, and we will always do our best to give you max support! |