- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Suitable Material: | |

|---|---|

| Die Head: | |

| Color: | |

| Warranty: | |

| Showroom location: | |

| Automation: | |

| Availability: | |

| Quantity: | |

DSB75

DAWSON

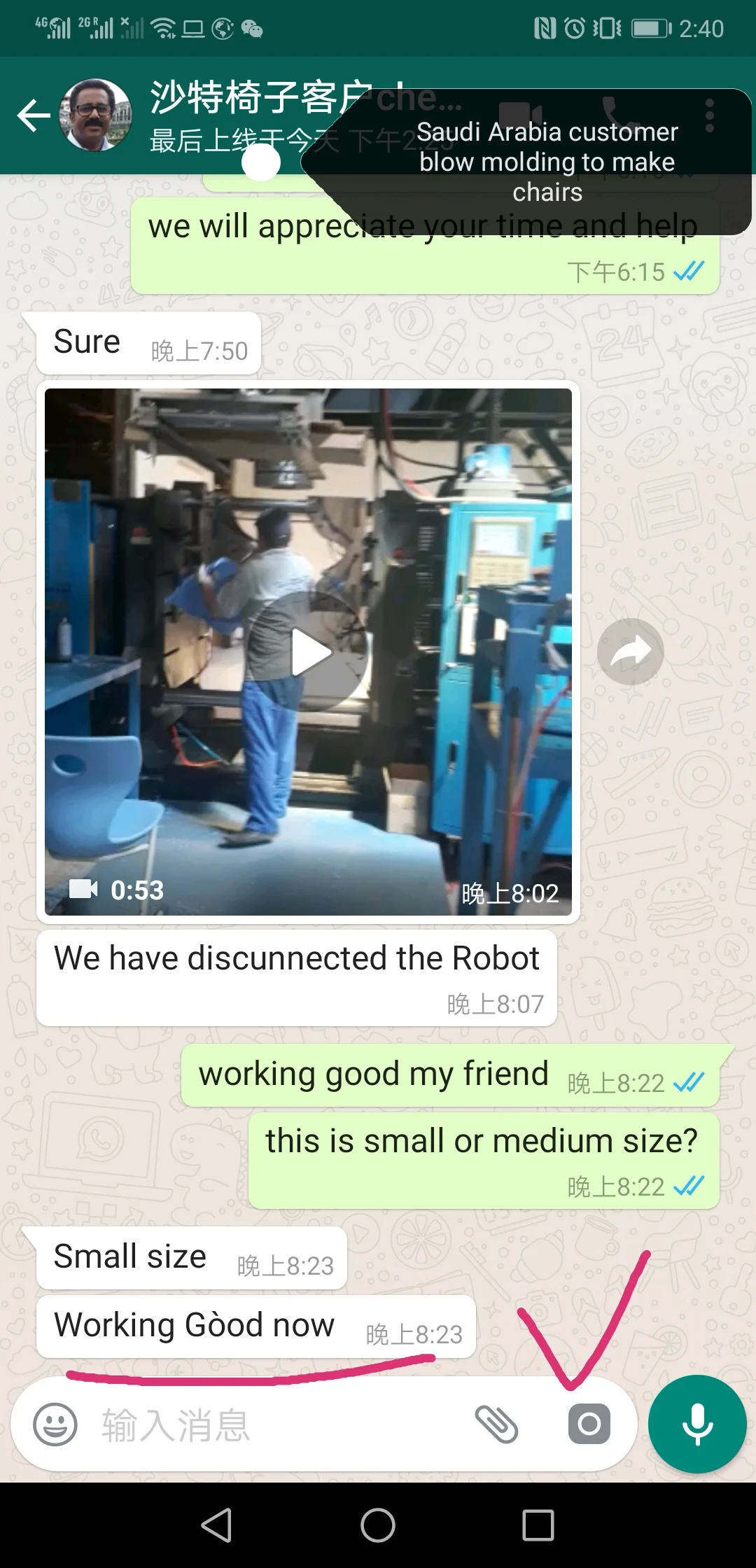

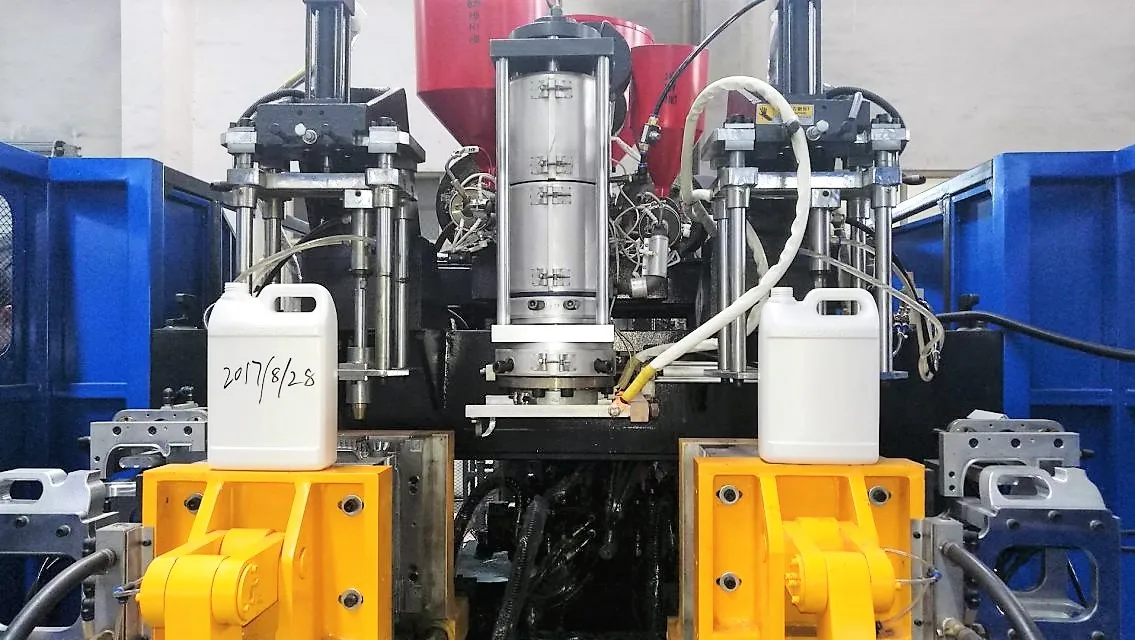

Plastic bottle production: The machine can produce plastic bottles of various sizes, from small 50ml bottles ideal for personal care products to larger 5L bottles suitable for industrial applications. Whether it's a slim - necked water bottle or a wide - mouthed bottle for food storage, the DSB65/75 can handle it with precision.

Jar and small container production: It is well - equipped to manufacture jars and small containers. These can be used for storing anything from condiments and spices to small household items. The machine ensures consistent wall thickness and smooth finishes, making them suitable for both consumer and industrial use.

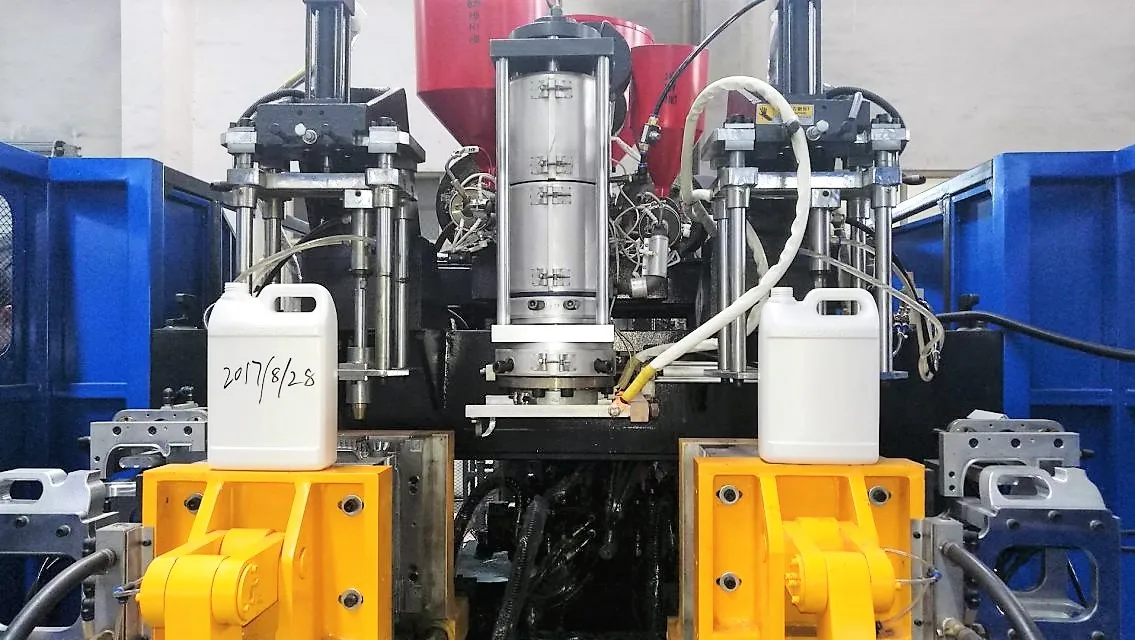

Jerrycan production: The DSB65/7

5 is capable of producing jerrycans with a capacity of up to 5L. Jerrycans are essential for storing fuel, water, and other liquids in various settings, from automotive to industrial and outdoor applications.

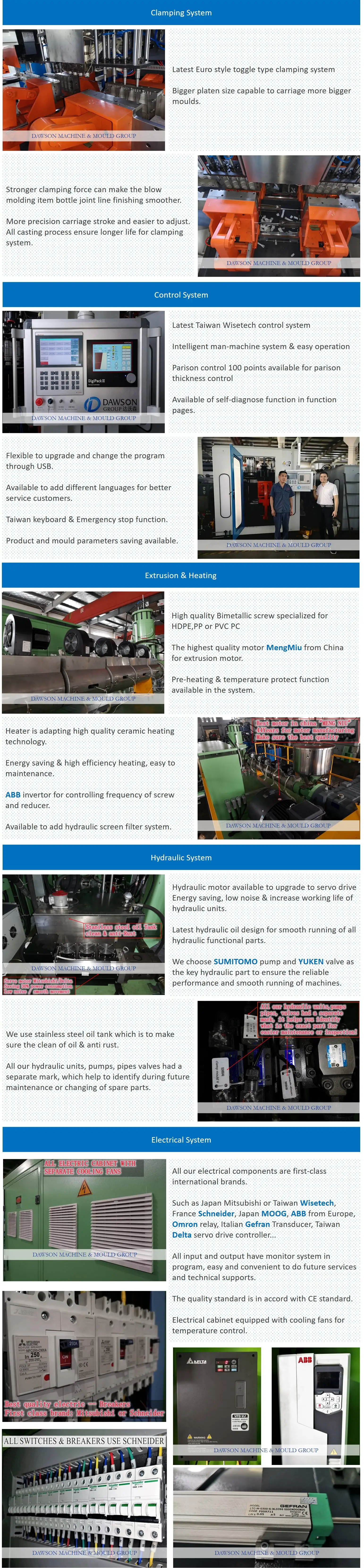

User - friendly interface: The bilingual operation panel is designed to be intuitive and easy to navigate. It allows operators to switch between English and Chinese language settings effortlessly. This feature is especially beneficial for operators who are more comfortable communicating in their native language, ensuring clear instructions and smooth operation.

Enhanced communication: Whether it's a domestic or international operator, the bilingual panel ensures effective communication. This not only helps in understanding the machine's functions but also in troubleshooting and maintenance. For example, an English - speaking operator can easily read the instructions in English, while a Chinese - speaking operator can switch to Chinese for better comprehension.

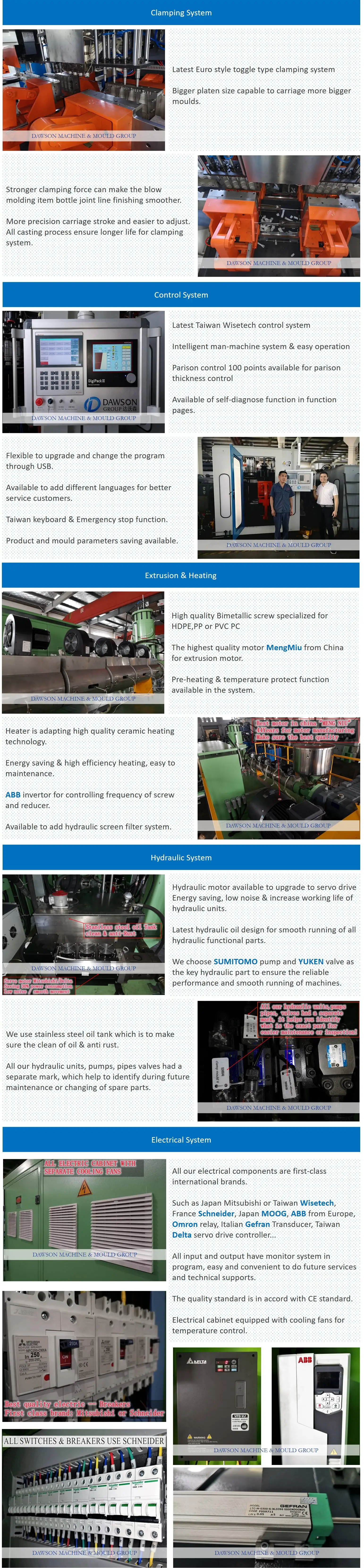

High - quality components: The machine is equipped with automatic configuration from world - renowned brands. These components are carefully selected to ensure the highest quality and performance. For instance, the extrusion system, which is responsible for melting and shaping the plastic, is made of high - grade materials that can withstand high temperatures and pressure.

Advanced technology integration: The automatic configuration from these brands brings advanced technologies to the machine. This includes state - of - the art control systems that can monitor and adjust various parameters during the blow molding process. For example, the machine can automatically adjust the blowing pressure and temperature based on the type of plastic being processed, ensuring optimal product quality.

Ease of use: The machine's design is centered around simplicity. The operator can easily understand the operation process, even with minimal training. The controls are straightforward, allowing for quick setup and adjustment. For example, the control panel has clearly labeled buttons for different functions, such as start, stop, and parameter adjustment.

Streamlined process: The simple operation also means that the production process can be easily optimized. This leads to increased productivity and reduced downtime. For instance, the machine can quickly switch between different production modes, allowing for efficient production of different types of plastic containers.

Increased efficiency: The high automation feature of the machine means that it can operate with minimal human intervention. This leads to a significant increase in production efficiency. The machine can continuously produce plastic containers at a high speed, while maintaining consistent quality. For example, the automatic feeding system can ensure a continuous supply of plastic raw materials, and the automated molding process can quickly produce finished products.

Quality control: The high automation also enables better quality control. The machine can monitor and adjust various parameters during the production process, ensuring that each product meets the highest standards. For example, the automated system can detect any defects in the plastic containers and reject them immediately, reducing waste and ensuring product quality.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |

Plastic bottle production: The machine can produce plastic bottles of various sizes, from small 50ml bottles ideal for personal care products to larger 5L bottles suitable for industrial applications. Whether it's a slim - necked water bottle or a wide - mouthed bottle for food storage, the DSB65/75 can handle it with precision.

Jar and small container production: It is well - equipped to manufacture jars and small containers. These can be used for storing anything from condiments and spices to small household items. The machine ensures consistent wall thickness and smooth finishes, making them suitable for both consumer and industrial use.

Jerrycan production: The DSB65/7

5 is capable of producing jerrycans with a capacity of up to 5L. Jerrycans are essential for storing fuel, water, and other liquids in various settings, from automotive to industrial and outdoor applications.

User - friendly interface: The bilingual operation panel is designed to be intuitive and easy to navigate. It allows operators to switch between English and Chinese language settings effortlessly. This feature is especially beneficial for operators who are more comfortable communicating in their native language, ensuring clear instructions and smooth operation.

Enhanced communication: Whether it's a domestic or international operator, the bilingual panel ensures effective communication. This not only helps in understanding the machine's functions but also in troubleshooting and maintenance. For example, an English - speaking operator can easily read the instructions in English, while a Chinese - speaking operator can switch to Chinese for better comprehension.

High - quality components: The machine is equipped with automatic configuration from world - renowned brands. These components are carefully selected to ensure the highest quality and performance. For instance, the extrusion system, which is responsible for melting and shaping the plastic, is made of high - grade materials that can withstand high temperatures and pressure.

Advanced technology integration: The automatic configuration from these brands brings advanced technologies to the machine. This includes state - of - the art control systems that can monitor and adjust various parameters during the blow molding process. For example, the machine can automatically adjust the blowing pressure and temperature based on the type of plastic being processed, ensuring optimal product quality.

Ease of use: The machine's design is centered around simplicity. The operator can easily understand the operation process, even with minimal training. The controls are straightforward, allowing for quick setup and adjustment. For example, the control panel has clearly labeled buttons for different functions, such as start, stop, and parameter adjustment.

Streamlined process: The simple operation also means that the production process can be easily optimized. This leads to increased productivity and reduced downtime. For instance, the machine can quickly switch between different production modes, allowing for efficient production of different types of plastic containers.

Increased efficiency: The high automation feature of the machine means that it can operate with minimal human intervention. This leads to a significant increase in production efficiency. The machine can continuously produce plastic containers at a high speed, while maintaining consistent quality. For example, the automatic feeding system can ensure a continuous supply of plastic raw materials, and the automated molding process can quickly produce finished products.

Quality control: The high automation also enables better quality control. The machine can monitor and adjust various parameters during the production process, ensuring that each product meets the highest standards. For example, the automated system can detect any defects in the plastic containers and reject them immediately, reducing waste and ensuring product quality.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |