- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Suitable Material: | |

|---|---|

| Die Head: | |

| Color: | |

| Warranty: | |

| Showroom location: | |

| Automation: | |

| Availability: | |

| Quantity: | |

DSB75

DAWSON

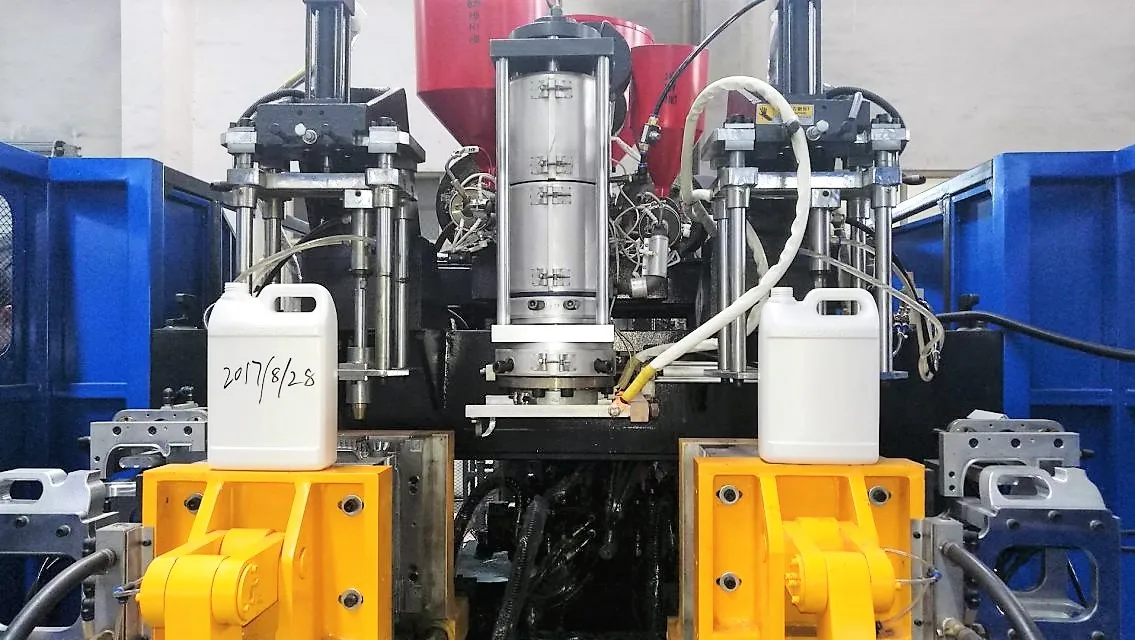

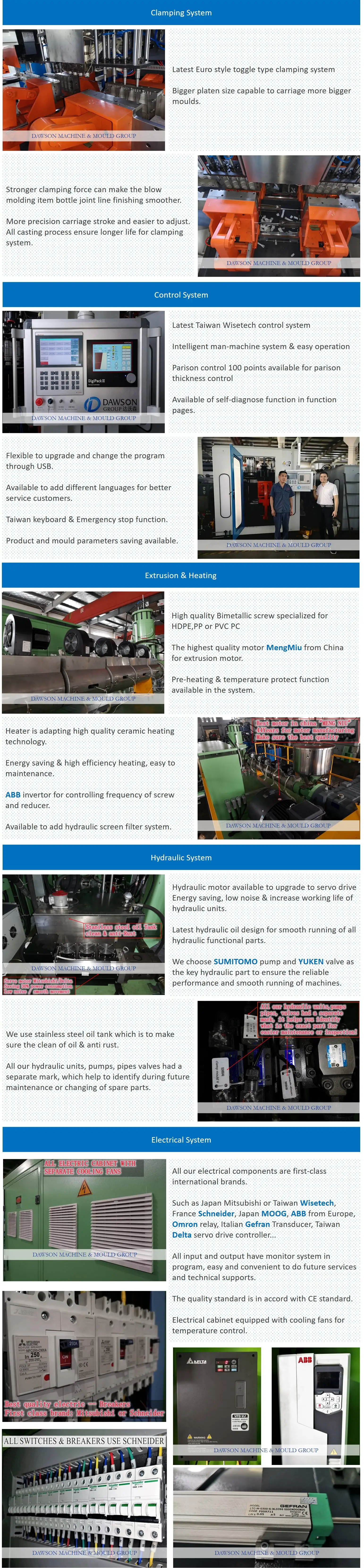

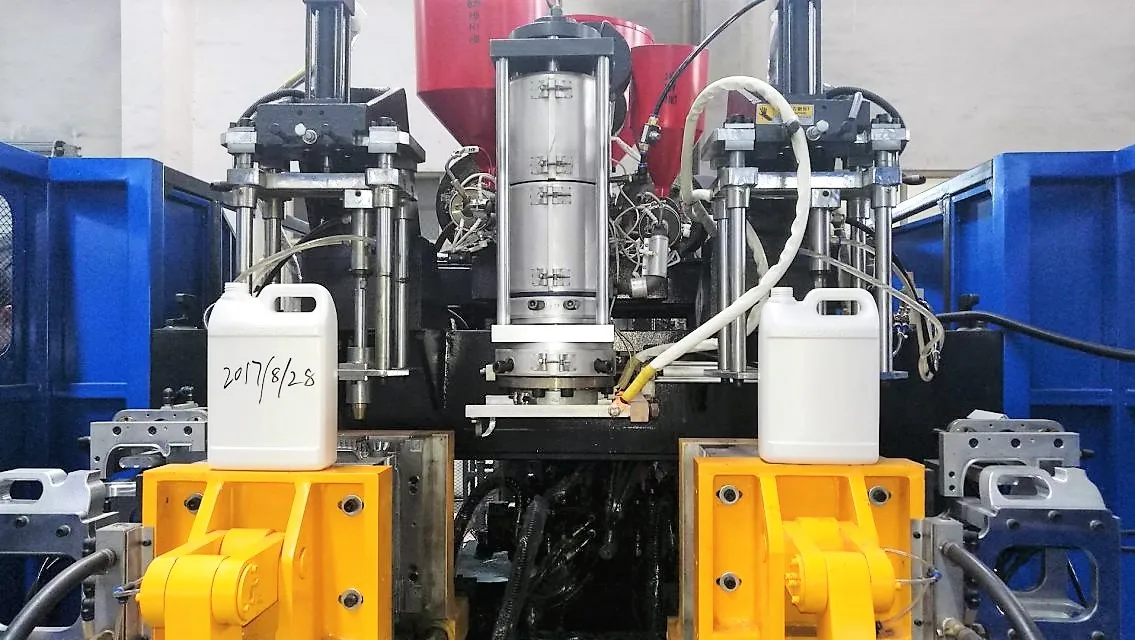

The Extrusion Blow Molding Machine DSB65/75 is a versatile and reliable solution designed for producing a wide range of plastic products, including bottles, jars, small containers, and jerrycans, with capacities ranging from 50ml to 5L. This machine is engineered to meet the diverse needs of industries such as food and beverage, household chemicals, pharmaceuticals, and more. It features an intuitive bilingual operation panel, ensuring ease of use for operators from various linguistic backgrounds. Additionally, the DSB65/75 is equipped with advanced automatic configurations sourced from world-renowned brands, delivering superior performance, precision, and reliability. These features not only simplify the operation process but also ensure high levels of automation, making it an ideal choice for businesses seeking efficient, user-friendly, and technologically advanced blow molding solutions.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |

The Extrusion Blow Molding Machine DSB65/75 is a versatile and reliable solution designed for producing a wide range of plastic products, including bottles, jars, small containers, and jerrycans, with capacities ranging from 50ml to 5L. This machine is engineered to meet the diverse needs of industries such as food and beverage, household chemicals, pharmaceuticals, and more. It features an intuitive bilingual operation panel, ensuring ease of use for operators from various linguistic backgrounds. Additionally, the DSB65/75 is equipped with advanced automatic configurations sourced from world-renowned brands, delivering superior performance, precision, and reliability. These features not only simplify the operation process but also ensure high levels of automation, making it an ideal choice for businesses seeking efficient, user-friendly, and technologically advanced blow molding solutions.

| Machine Model | Max. Bottle size | Production forecast | |

| ABLB65 | Double Station Double Head | 1L | 450~480 BPH |

| Double Station Single Head | 5L | 280~320 BPH | |

Technical Parameters

| Name | Units | ABLB65II | ABLB75II |

| Max.product volume | L | 3.5 | 8 |

| Screw diameter | MM | 65 | 75 |

| Screw drive power | KW | 18.5 | 22 |

| Output of HDPE | KG/H | 75 | 100 |

| Oil pump drive power | KW | 7.5 | 7.5 |

| Clamping force | KN | 65 | 80 |

| Max.size of mold | MM | 320×350 | 400×430 |

| Template size | MM | 290×320 | 380×420 |

| Mold stroke | MM | 150-500 | 170-520 |

| Max.die diameter | MM | 170 | 170 |

| Size of machine | L×W×H | 3.9×2.2×2.6 | 4.2×2.2×2.7 |

| Weight of machine | TON | 6.5 | 7.5 |