- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

ABLB100

DAWSON

Automatic Double Station Double Head Extrusion Blow Molding Machines For hanging bottle pp

DESCRIPTION

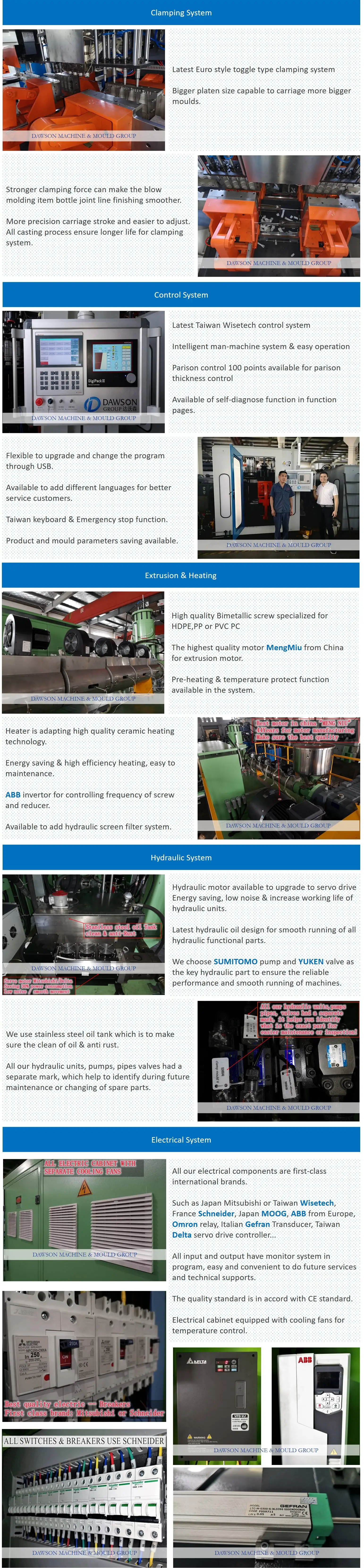

The extrusion blow molding process involves melting plastic resin and extruding it into a hollow tube, called a parison. The parison is then placed in a mold, and compressed air is blown into it, causing the plastic to expand and take the shape of the mold. After the plastic cools and solidifies, the mold is opened, and the finished bottle is ejected.

Material compatibility: PP (polypropylene) is a commonly used plastic material for blow molding due to its favorable properties such as chemical resistance, durability, and lightweight nature. Ensure that the machine you choose is specifically designed to process PP and can handle the specific characteristics of this material effectively.

Output capacity: The output capacity of a blow molding machine refers to the number of bottles it can produce within a given time frame. Depending on your production requirements, you'll need to consider the machine's speed, cycle time, and overall output capacity to ensure it meets your volume needs.

Energy efficiency: Energy consumption is a significant consideration in manufacturing processes. Look for machines that incorporate energy-efficient features such as servo motors, advanced heating technology, or energy-saving modes. These features can help reduce operational costs and minimize environmental impact.

Machine control and automation: Advanced blow molding machines often come equipped with user-friendly control systems and automation features. These systems allow for precise control over various process parameters, such as parison thickness, cooling time, and mold movement. Consider the level of automation and control offered by the machine to ensure ease of operation and consistent production quality.

Technical Parameter

| Name | Units | ABLB100II |

| Max.product volume | L | 0.5 |

| Screw diameter | MM | 100 |

| Screw drive power | KW | 18.5 |

| Output of HDPE | KG/H | 75 |

| Oil pump drive power | KW | 7.5 |

| Clamping force | KN | 65 |

| Max.size of mold | MM | 320×350 |

| Template size | MM | 290×320 |

| Mold stroke | MM | 150-500 |

| Max.die diameter | MM | 170 |

| Size of machine | L×W×H | 4.5×3×2.6 |

| Weight of machine | TON | 11 |

Application

|  |

Automatic Double Station Double Head Extrusion Blow Molding Machines For hanging bottle pp

DESCRIPTION

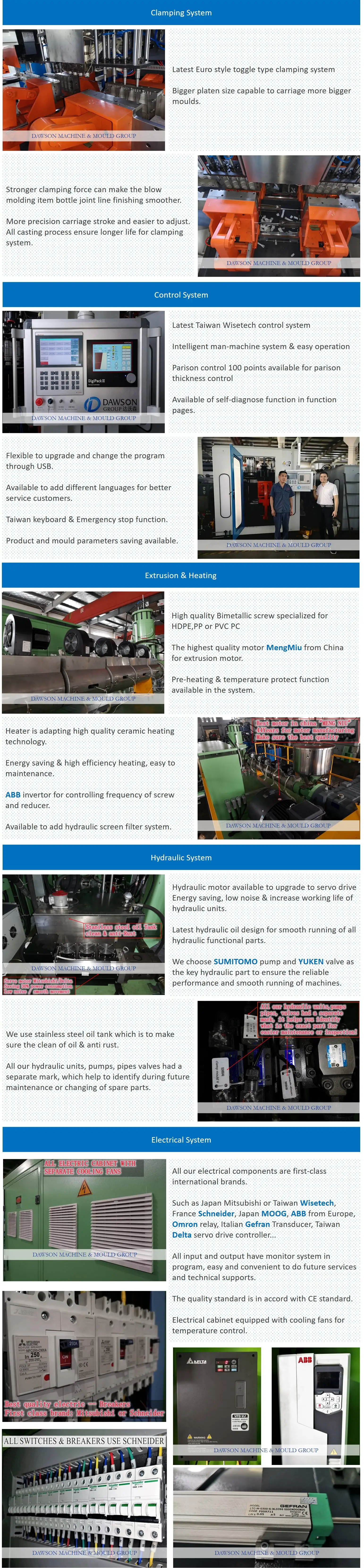

The extrusion blow molding process involves melting plastic resin and extruding it into a hollow tube, called a parison. The parison is then placed in a mold, and compressed air is blown into it, causing the plastic to expand and take the shape of the mold. After the plastic cools and solidifies, the mold is opened, and the finished bottle is ejected.

Material compatibility: PP (polypropylene) is a commonly used plastic material for blow molding due to its favorable properties such as chemical resistance, durability, and lightweight nature. Ensure that the machine you choose is specifically designed to process PP and can handle the specific characteristics of this material effectively.

Output capacity: The output capacity of a blow molding machine refers to the number of bottles it can produce within a given time frame. Depending on your production requirements, you'll need to consider the machine's speed, cycle time, and overall output capacity to ensure it meets your volume needs.

Energy efficiency: Energy consumption is a significant consideration in manufacturing processes. Look for machines that incorporate energy-efficient features such as servo motors, advanced heating technology, or energy-saving modes. These features can help reduce operational costs and minimize environmental impact.

Machine control and automation: Advanced blow molding machines often come equipped with user-friendly control systems and automation features. These systems allow for precise control over various process parameters, such as parison thickness, cooling time, and mold movement. Consider the level of automation and control offered by the machine to ensure ease of operation and consistent production quality.

Technical Parameter

| Name | Units | ABLB100II |

| Max.product volume | L | 0.5 |

| Screw diameter | MM | 100 |

| Screw drive power | KW | 18.5 |

| Output of HDPE | KG/H | 75 |

| Oil pump drive power | KW | 7.5 |

| Clamping force | KN | 65 |

| Max.size of mold | MM | 320×350 |

| Template size | MM | 290×320 |

| Mold stroke | MM | 150-500 |

| Max.die diameter | MM | 170 |

| Size of machine | L×W×H | 4.5×3×2.6 |

| Weight of machine | TON | 11 |

Application

|  |