DAWSON MACHINERY & MOULD GROUP

Extrusion Blow Molding Machine ABLB65

PET Blow Molding Machine: The Ideal Choice for Manufacturing Multi-functional Plastic Containers

Wide Range of Applications

Product Diversity

The PET blow molding machine is suitable for making various plastic bottles, jars, small containers, and jerrycans with capacities ranging from 50ml to 5L. Whether it's the delicate cosmetic bottles, the commonly used beverage bottles, or the large-capacity jerrycans, all can be efficiently produced by this machine. Such a wide range of applicability meets the diverse needs of different industries and consumers for plastic containers.

Advanced Configuration

Bilingual Operation Panel

To facilitate the operation by users from different regions, the blow molding machine is equipped with a bilingual operation panel. Whether in English or Chinese, users can easily understand the operation instructions. This design greatly improves the convenience of operation, enabling the operators to quickly master the usage of the machine and reducing operational errors caused by language barriers.

Automatic Configuration of World-renowned Brands

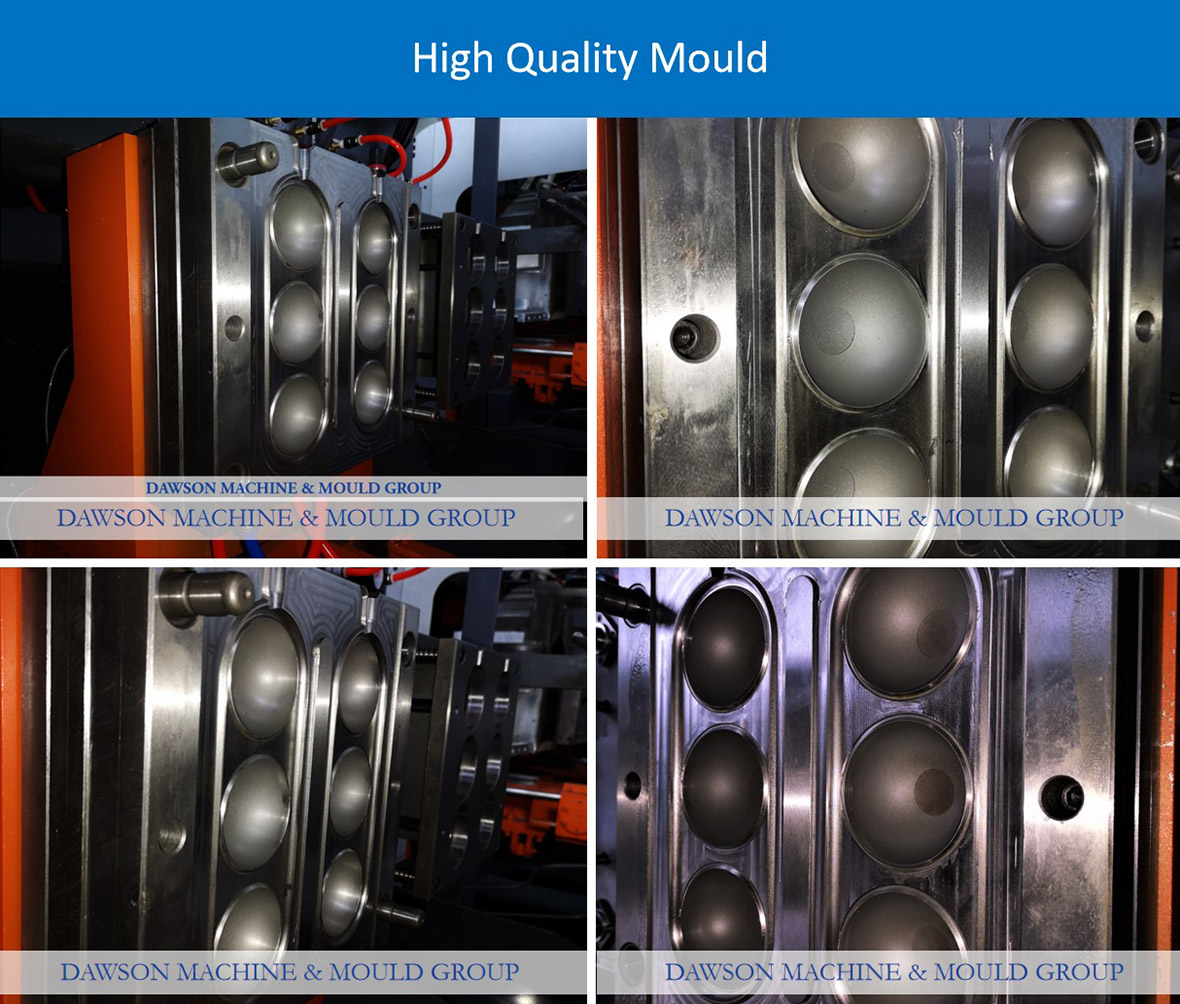

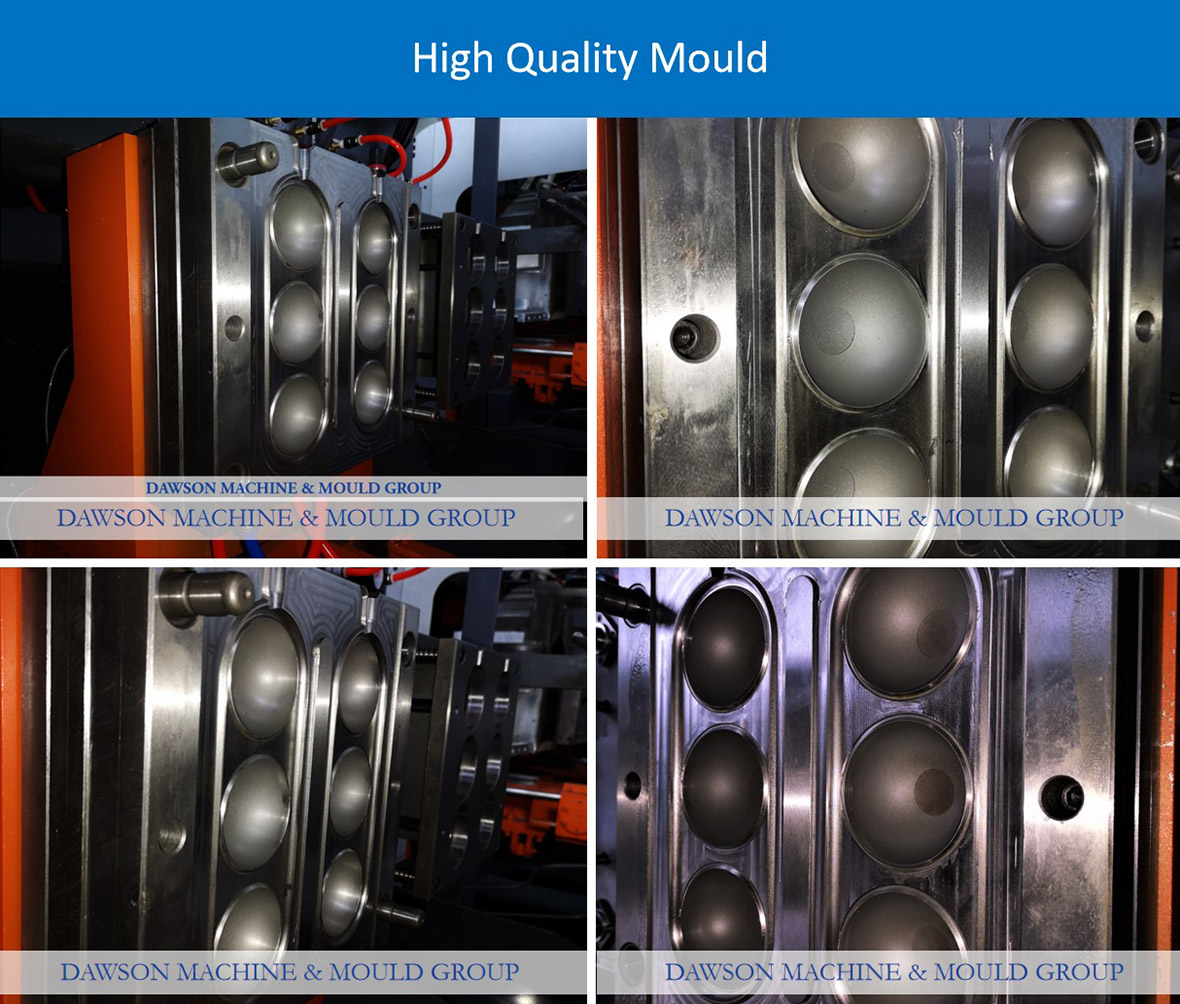

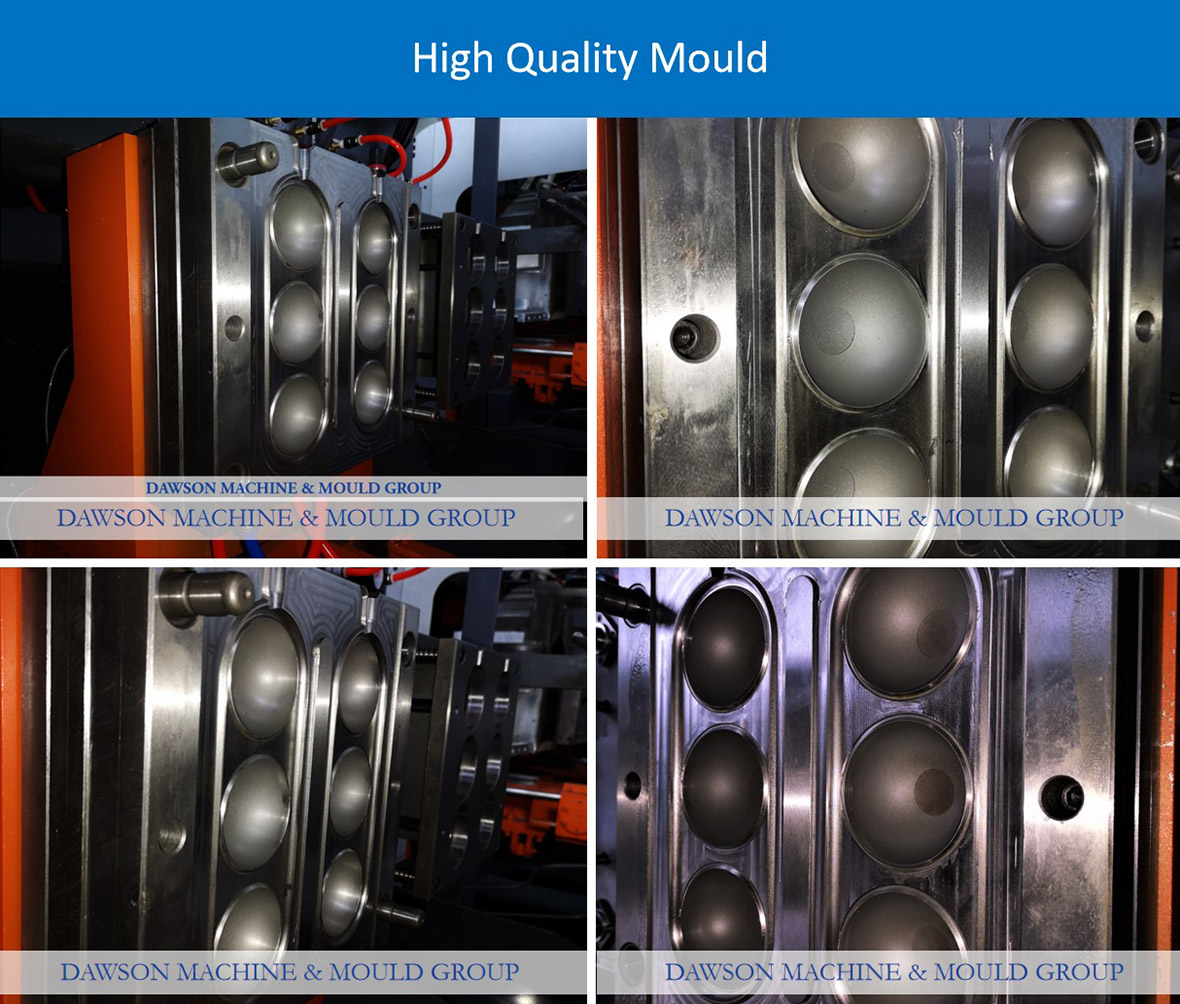

The entire blow molding machine adopts the automatic configuration from world-renowned brands to ensure its stable and reliable performance. The advanced technologies and high-quality components of these brands endow the blow molding machine with excellent performance and durability. From the precise mold design to the efficient blow molding process, every link reflects an advanced technological level, providing a powerful guarantee for producing high-quality plastic containers.

Operational Advantages

Simple Operation

The operation design of the PET blow molding machine is quite simple and easy to understand. Even those who are new to blow molding machines can become familiar with the operation process in a short time. Thanks to its intuitive operation interface and clear instructions, operators can easily complete various operation tasks, reducing the operation difficulty and training costs.

High Degree of Automation

Through advanced automation technology, the blow molding machine realizes highly automated production. From the transportation, heating, blowing of plastic raw materials to the product molding, the entire process requires no manual intervention. This not only improves production efficiency but also reduces the impact of human factors on product quality. The automated production mode enables the machine to operate continuously and stably, greatly increasing the production output and quality.

Application Scenarios

Industrial Production

In the industrial field, the PET blow molding machine is widely used in the production of various plastic containers. For example, the chemical industry needs a large number of plastic jars to store chemicals; the food industry requires plastic bottles to package beverages, sauces and other products. The blow molding machine can meet the different needs of industrial production and provide efficient and stable production solutions for enterprises.

Daily Life Consumption

In daily life, the plastic bottles, jars and other products produced by the PET blow molding machine can also be seen everywhere. Whether it's the cooking oil bottles, laundry detergent bottles used at home or the packaging bottles for personal care products, they are all inseparable from the production of the blow molding machine. These products not only meet the needs of consumers for packaging containers but also bring convenience to life.

Commercial Field

The commercial field also has a wide range of demands for plastic containers. Supermarkets, convenience stores and other retail places need a large number of plastic bottles and jars to display and sell goods. The products produced by the blow molding machine have good appearance and quality and can meet the requirements of commercial packaging. Meanwhile, the customized production of plastic containers also provides more business opportunities for enterprises.

In conclusion, the PET blow molding machine, with its wide range of applications, advanced configuration, simple operation and high degree of automation, has become the ideal choice for the plastic container manufacturing industry. Whether in industrial production or daily life consumption, it can play an important role and meet the needs of different users.

Name | Units | ABLB65II |

Max.product volume | L | 3.5 |

Screw diameter | MM | 65 |

Screw drive power | KW | 18.5 |

Output of HDPE | KG/H | 75 |

Oil pump drive power | KW | 7.5 |

Clamping force | KN | 65 |

Max.size of mold | MM | 320×350 |

Template size | MM | 290×320 |

Mold stroke | MM | 150-500 |

Max.die diameter | MM | 170 |

Size of machine | L×W×H | 3.9×2.2×2.6 |

Weight of machine | TON | 6.5 |